Web Menu

Product Search

Exit Menu

Should the limit clearance of the truck scale be checked regularly?

The limit clearance of the truck scale needs to be checked regularly, and the specific reasons and importance can be introduced in the following points:

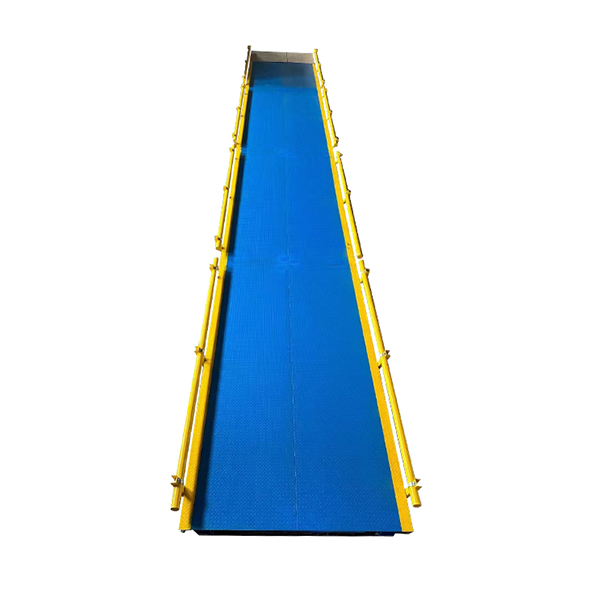

1. Ensure the normal movement of the platform

The appropriate limit clearance can ensure sufficient free movement space for the weighing platform during the weighing process, avoiding jamming.

A too small gap may cause friction or collision between the weighing platform and the limit device, affecting weighing stability.

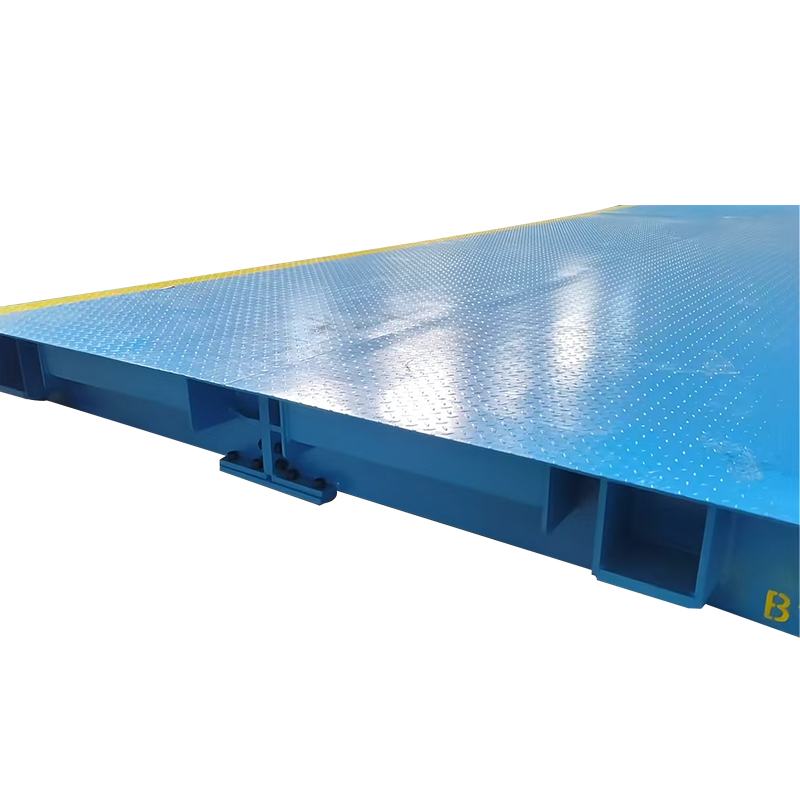

2. Prevent equipment damage

If the limit clearance is too large, the balance platform may move excessively under stress, causing structural deformation or damage.

Too small a gap can cause long-term stress on the limit device, leading to wear and even breakage.

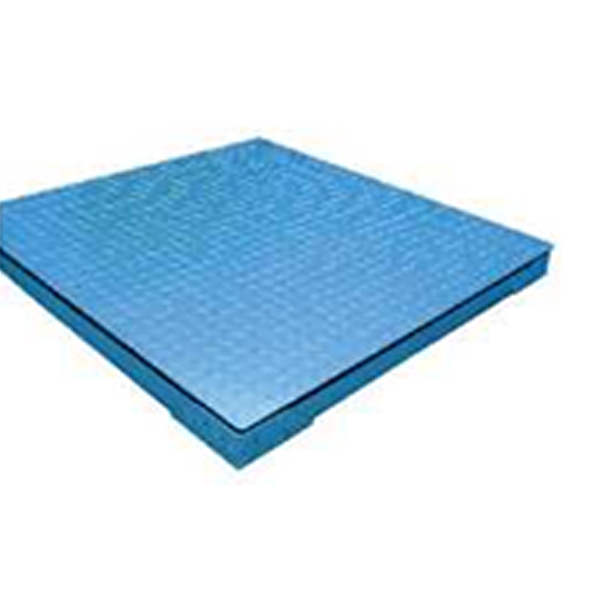

3. Ensure weighing accuracy

Abnormal limit clearance can lead to uneven force distribution on the weighing platform, abnormal sensor data, and thus affect weighing accuracy.

Regularly checking and adjusting the limit clearance helps maintain the stability and accuracy of weighing data.

4. Prevent safety hazards

Inappropriate limit clearance may cause the platform to suddenly jam or shift, affecting the safety of vehicle loading and unloading.

Checking the limit clearance is an important measure to ensure operational safety.

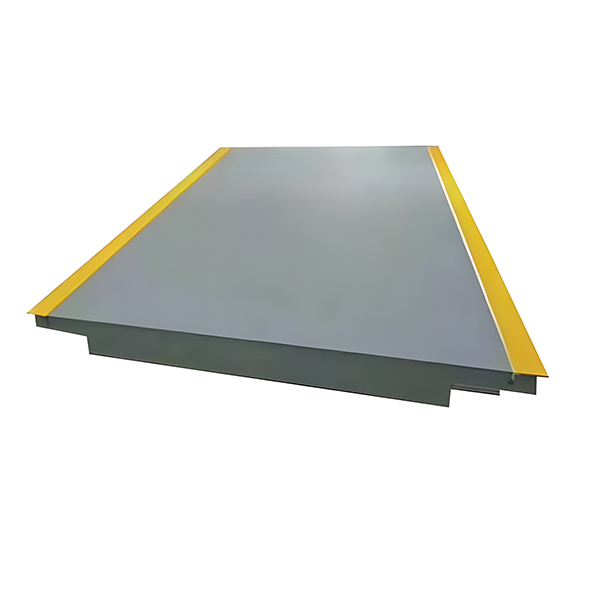

5. Extend the service life of equipment

By regularly checking and adjusting the limit clearance, premature wear or damage of components caused by abnormal clearance can be avoided.

Keep the equipment in good condition and reduce the frequency of maintenance and replacement.

6. Easy maintenance and low cost

The inspection and adjustment of limit clearance is simple, with low periodic maintenance costs and significant effects.

Suggest developing a regular inspection plan and incorporating it into the daily maintenance process.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体