Web Menu

Product Search

Exit Menu

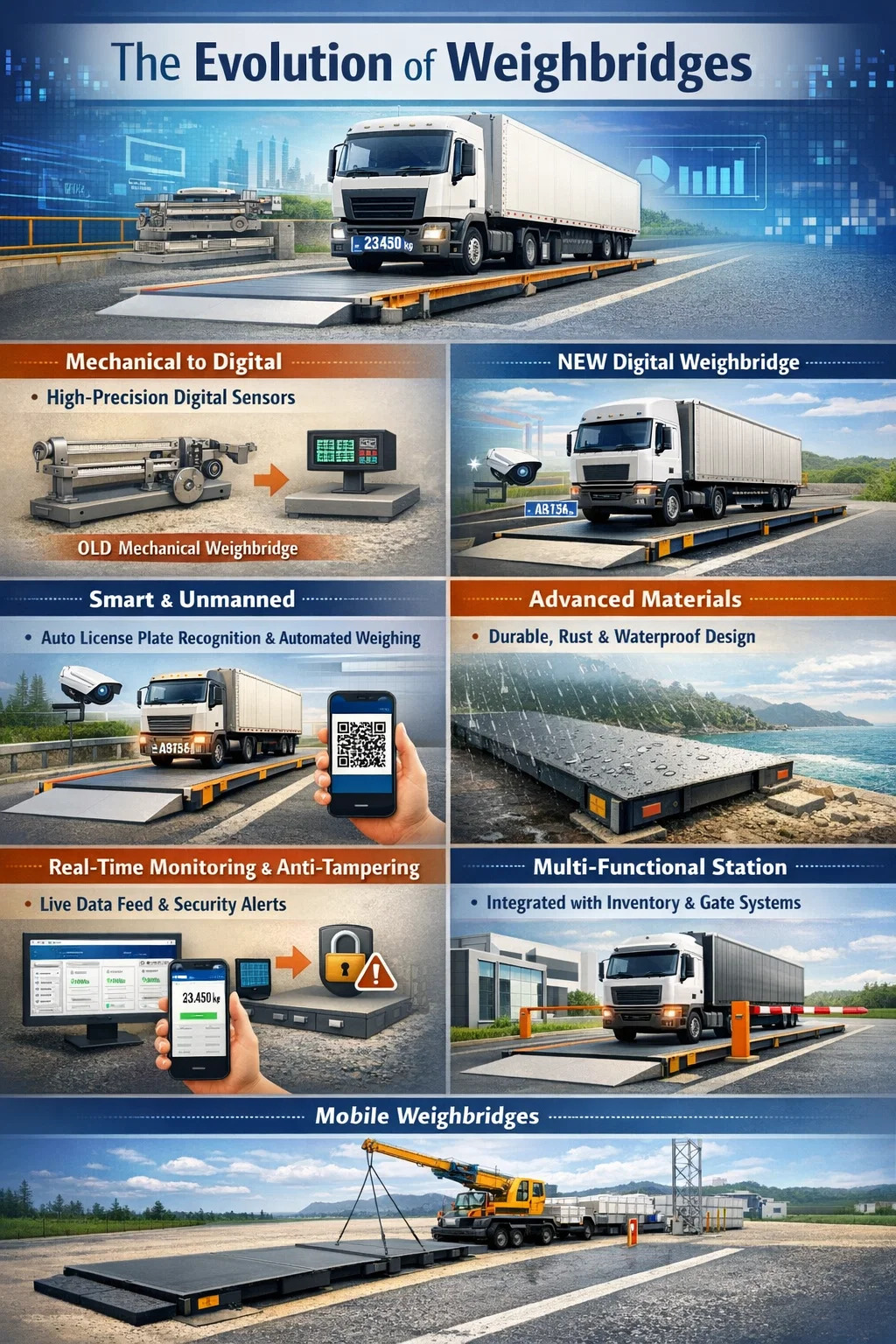

What happened to weighbridge?

If you're asking about the changes weighbridges have undergone over the years, or what they've become in modern industry, then "a complete transformation" is an apt description. They are no longer the bulky, slow-reacting, error-prone lumps of iron they once were.

Here are some significant changes that have occurred in the evolution of weighbridges:

1. From "Mechanical" to "Digital"

Previous weighbridges relied on complex lever and spring structures, like a magnified version of old-fashioned beam scales. They were not only bulky but also particularly troublesome to maintain.

Now: They have become completely electronic devices. High-precision digital sensors are installed under the platform, providing extremely fast response times and highly sensitive digital readings, eliminating the need to manually adjust weights like before.

2. Becoming Smarter and Unmanned

Previously, a dedicated operator had to sit in a booth to record weighings; now, many weighbridges are fully automated.

Camera recognition: When a truck drives onto the weighbridge, a camera automatically captures the license plate, and the system directly identifies the vehicle.

Automatic settlement: Weight data is automatically transmitted to the cloud. The driver simply swipes a card or scans a QR code, and the weigh slip is automatically sent to their mobile phone. The entire process requires no human supervision.

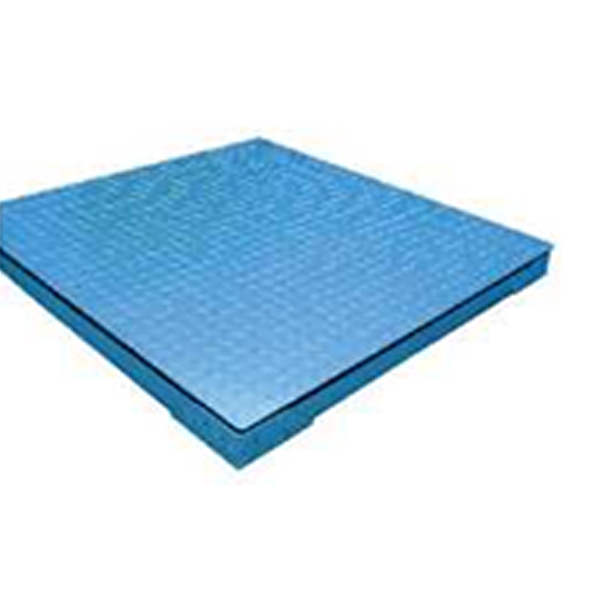

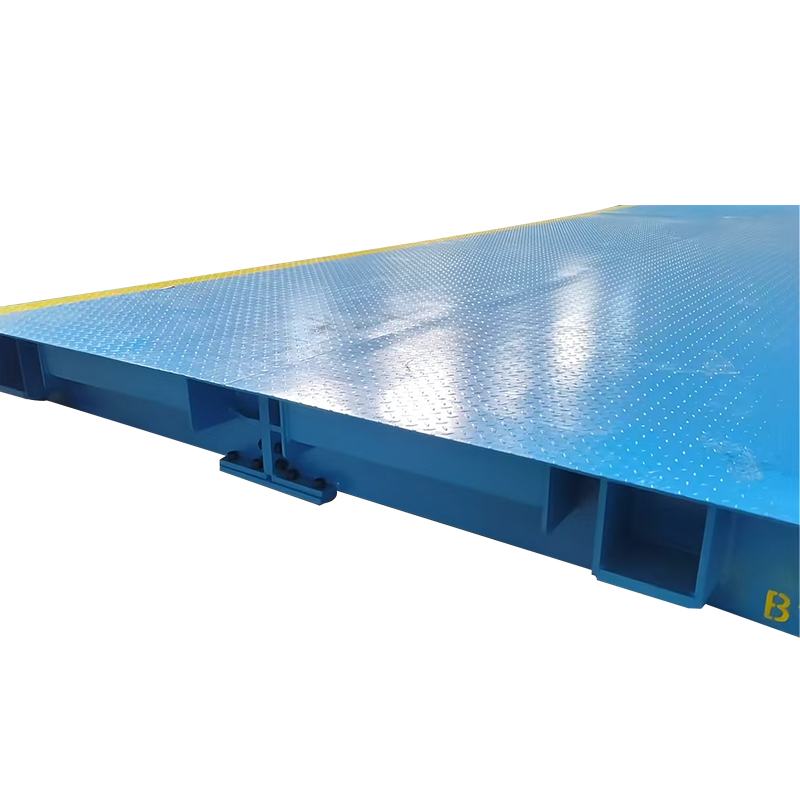

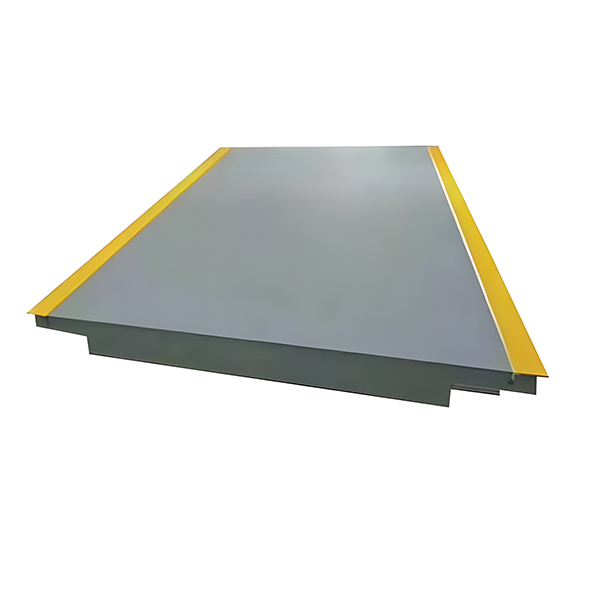

3. Upgraded Installation and Materials

Installing a weighbridge used to be as laborious as building a house; now it's much more flexible.

Structural improvements: Modern steel welding technology is more advanced, making the scale body stronger yet lighter.

Corrosion protection: Modern equipment includes strong rust and waterproof features. Even if constantly exposed to rain or a salty marine environment, the internal electronic components are less likely to fail.

4. Real-time Monitoring and Anti-Tampering

Previously, people would "tamper" with the scales, such as placing bricks under the platform or exploiting visual errors.

Anti-interference technology: Modern weighbridges have added anti-tampering systems. If someone places an interference device nearby, or if the vehicle is not completely stationary, the system will trigger an alarm.

Data transparency: The owner can see the real-time weight of every vehicle on the scale from their office or even at home using their mobile phone. Modifying the data is virtually impossible.

5. From "Single Function" to "Multi-functional Station"

Modern weighbridges often do more than just weigh.

They are frequently integrated with factory automatic gates and inventory management software. As soon as a vehicle is weighed, the inventory data in the warehouse is automatically updated, and the accounting department automatically generates an invoice.

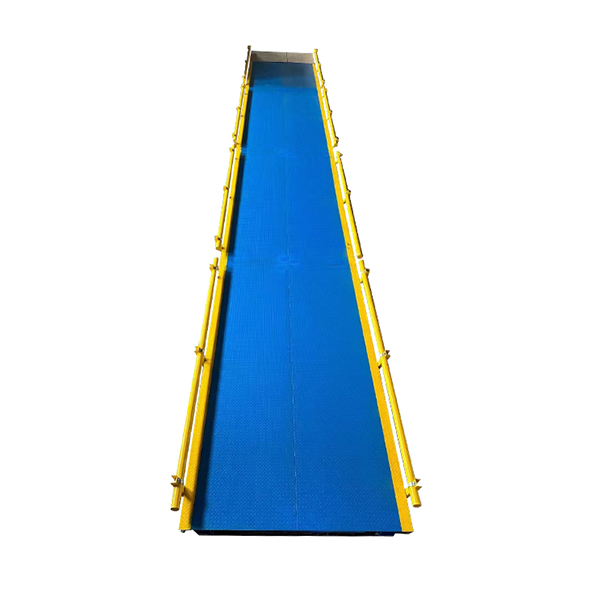

6. The emergence of mobile weighbridges

Previously, weighbridges had to be permanently fixed in one location. Now, technology allows these large weighing scales to be constructed like a "jigsaw puzzle," using several panels laid on a flat surface. Once a construction project is completed, the weighbridge can be easily lifted and transported to the next site for continued use.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体