Web Menu

Product Search

Exit Menu

What is a truck scale?

Basic definition

A truck scale is a large electronic weighing device used to weigh vehicles and their loads, typically installed in fixed locations such as factories, logistics centers, toll stations, etc., to accurately measure the weight of heavy vehicles such as trucks and wagons.

Main purpose

Trade settlement: measurement of the buying and selling of bulk commodities such as coal, grain, and building materials.

Logistics management: Calculate the load capacity of transportation vehicles to ensure that they are not overloaded.

Production control: Weighing management of materials entering and leaving the warehouse within the factory.

Law enforcement supervision: Highway overloading control stations detect whether vehicles exceed the limit and overload.

Core components

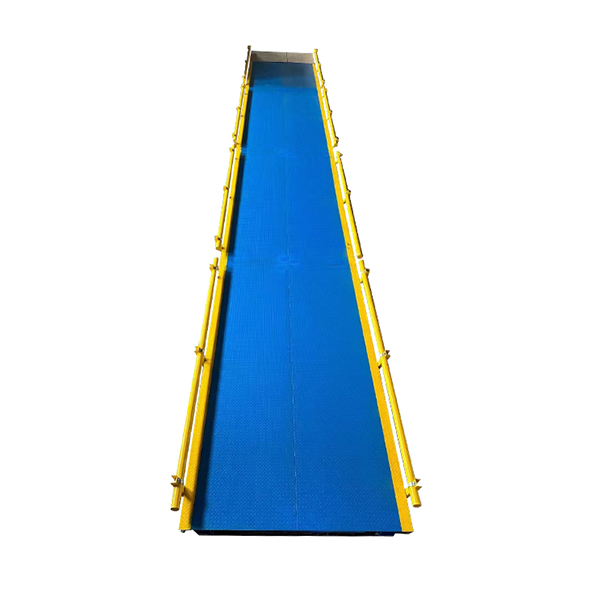

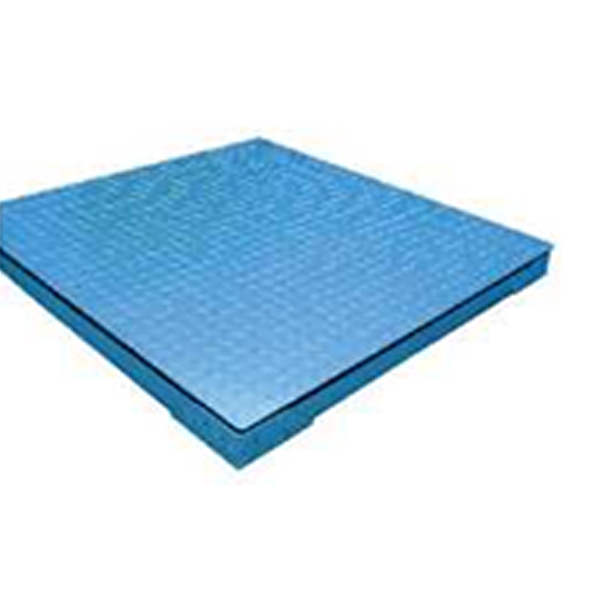

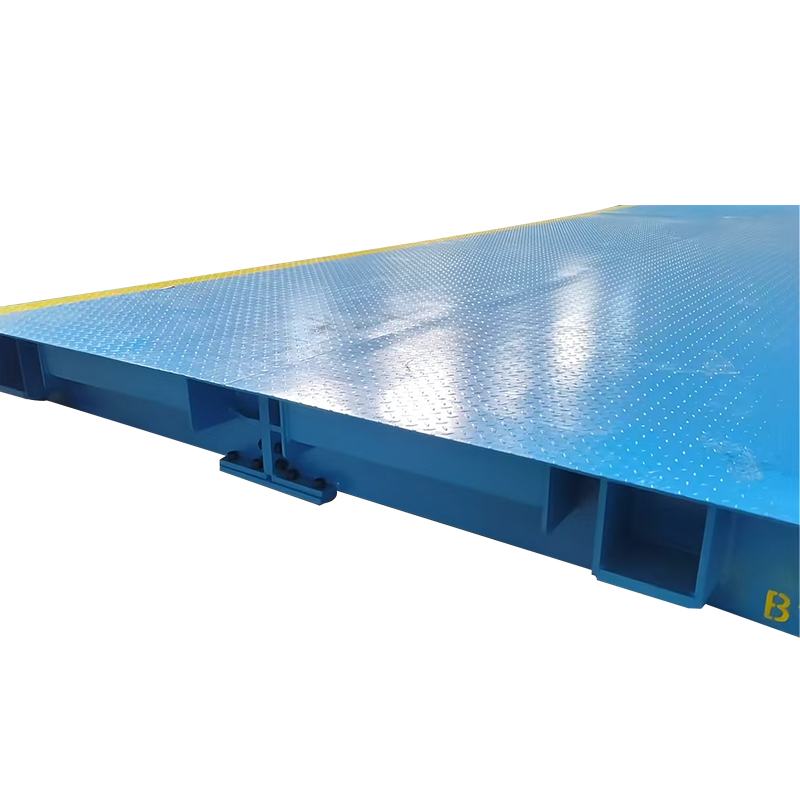

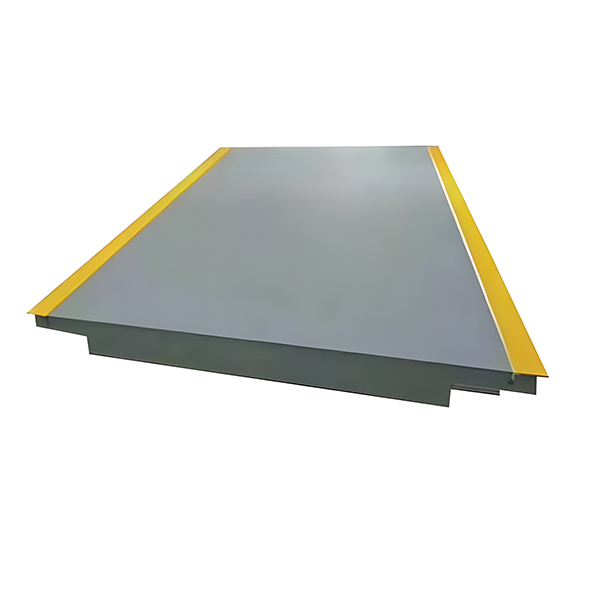

Scale platform: a platform that carries vehicles, usually made of steel structure or concrete.

Weighing sensor: a key component that converts weight signals into electrical signals.

Instrument (display terminal): Real time display and recording of weighing data.

Infrastructure: The concrete or steel foundation that supports the entire truck scale.

Working principle

After the vehicle drives onto the weighing platform, the weight is converted into an electrical signal through sensors, transmitted to the instrument panel for processing and displaying the weight data.

Common types

Electronic car scale: using digital sensors, high precision, and can be managed through networking.

Mechanical truck scale: Traditional lever structure, simple maintenance but low accuracy.

Portable car scale: movable installation, suitable for temporary weighing needs.

key features

Large weighing range: Vehicles that can weigh tens to hundreds of tons.

High precision: The error is usually controlled within ± 0.1%, meeting the requirements of trade settlement.

Strong durability: Suitable for harsh outdoor environments such as sun exposure, rain, snow, and vibration.

Precautions for use

The vehicle needs to drive completely into the weighing platform and stop steadily before reading the data.

Regular calibration and maintenance to ensure weighing accuracy.

Avoid overloading or impacting the weighing platform to prevent damage to the sensor.

| Category | Description |

| Definition | Large weighing devices designed to measure the weight of vehicles and their loads, typically installed at fixed locations. |

| Primary Uses | • Trade commerce (e.g., bulk goods transactions) • Logistics management • Production inventory control • Law enforcement (overload monitoring) |

| Key Components | • Weighing platform (steel/concrete) • Load cells (weight-to-electronic signal conversion) • Indicator/display terminal • Foundation (support structure) |

| Working Principle | Vehicle weight is transferred through load cells, converted to electronic signals, and displayed/recorded by the terminal. |

| Common Types | • Electronic weighbridges (digital, high precision) • Mechanical weighbridges (lever-based, robust) • Portable axle scales (temporary installations) |

| Key Features | • High capacity (tens to hundreds of tons) • Legal-for-trade accuracy (±0.1% typical) • Weather/impact-resistant construction |

| Operational Guidelines | • Vehicles must be fully positioned and stationary • Requires periodic calibration/maintenance • Avoid overloading or dynamic impacts |

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体