Web Menu

Product Search

Exit Menu

How long do truck scales last?

The lifespan of truck scales is like the lifespan of a truck—it all depends on how you use and maintain them.

Content

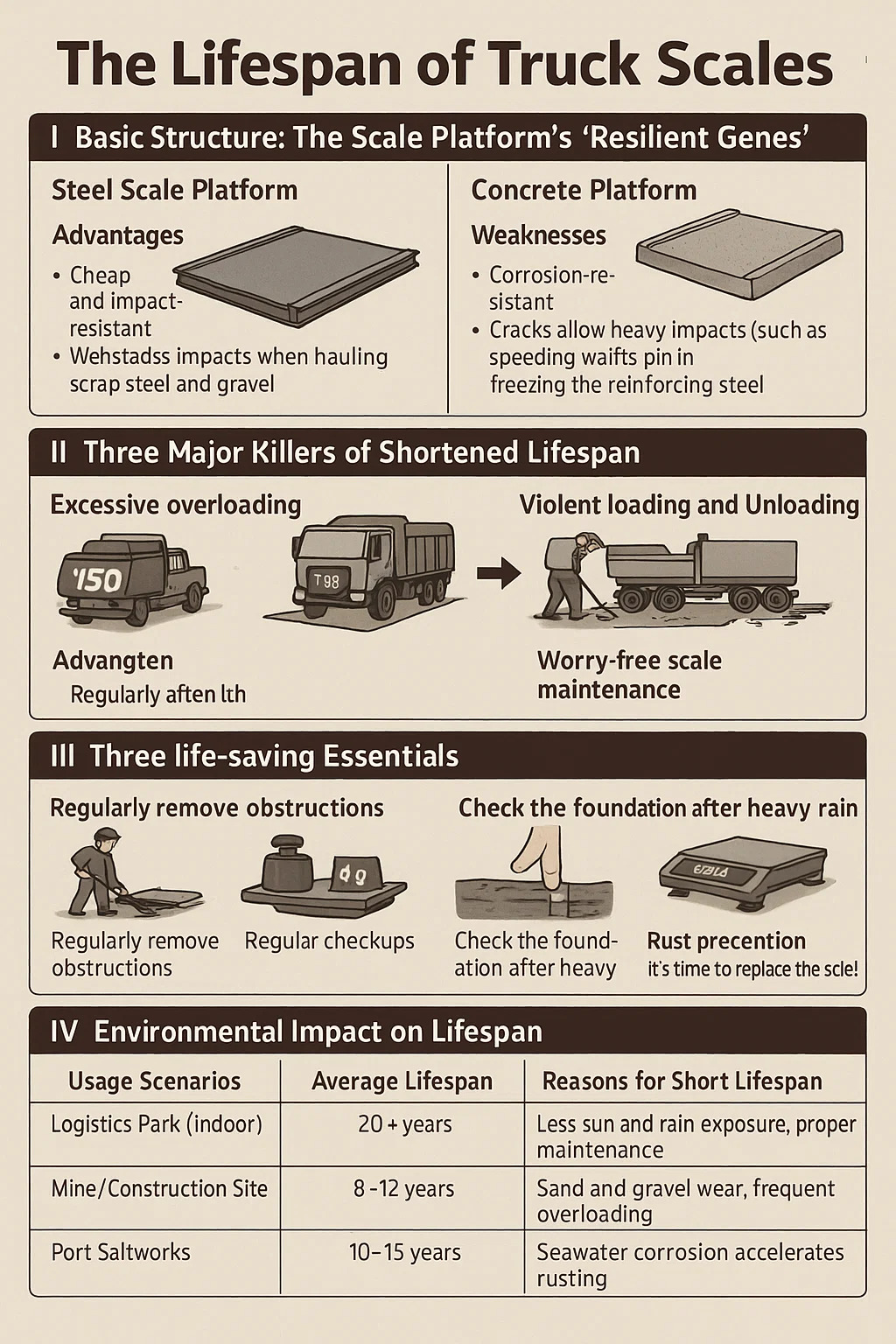

I. Basic Structure: The Scale Platform's "Resilient Genes"

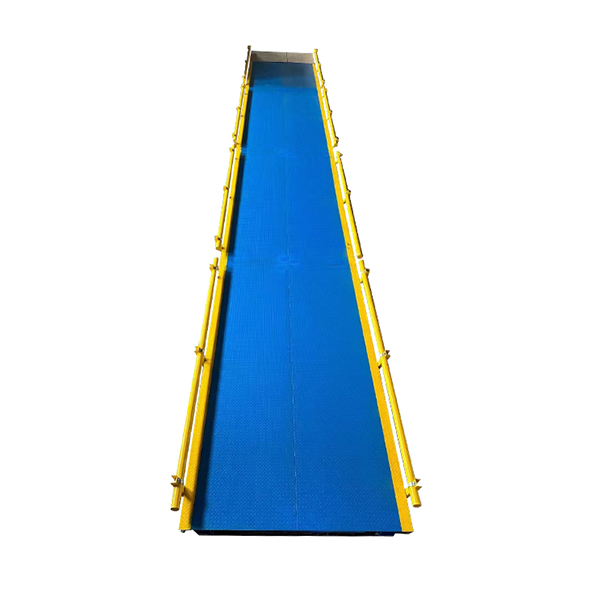

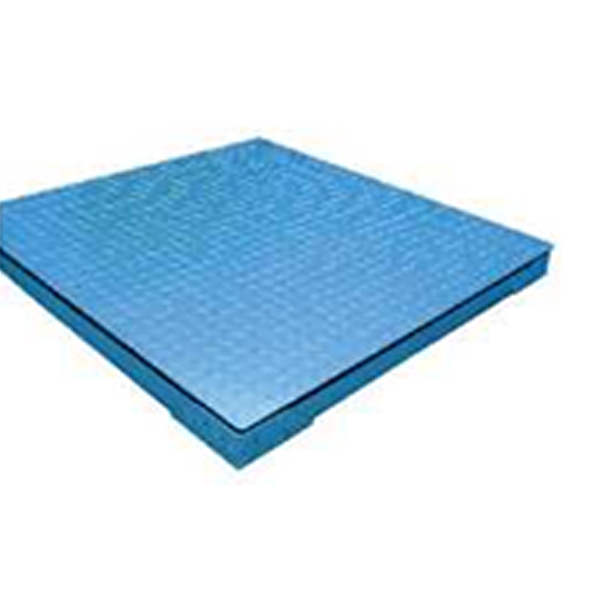

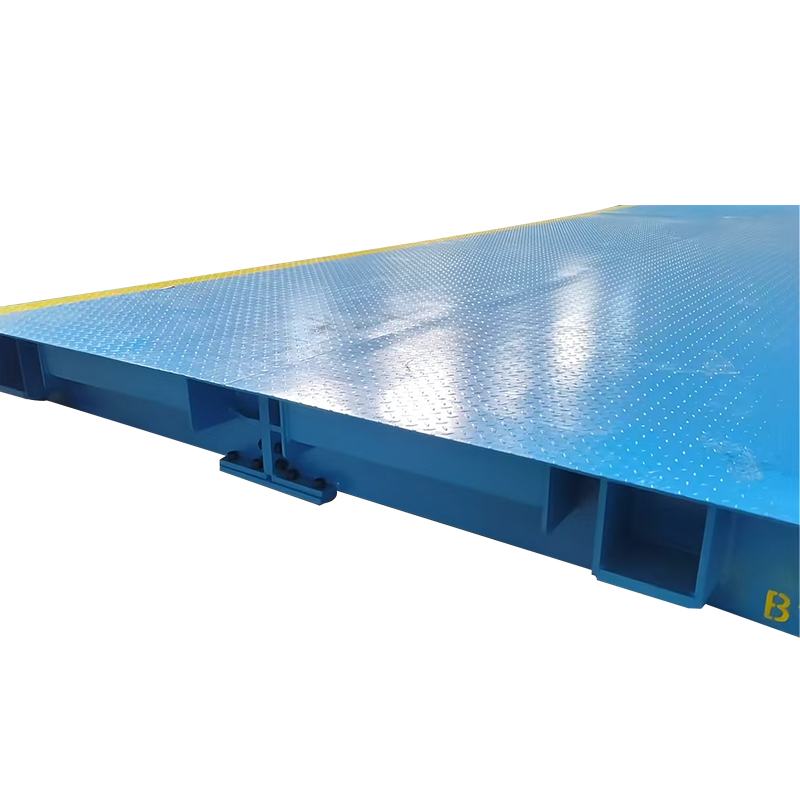

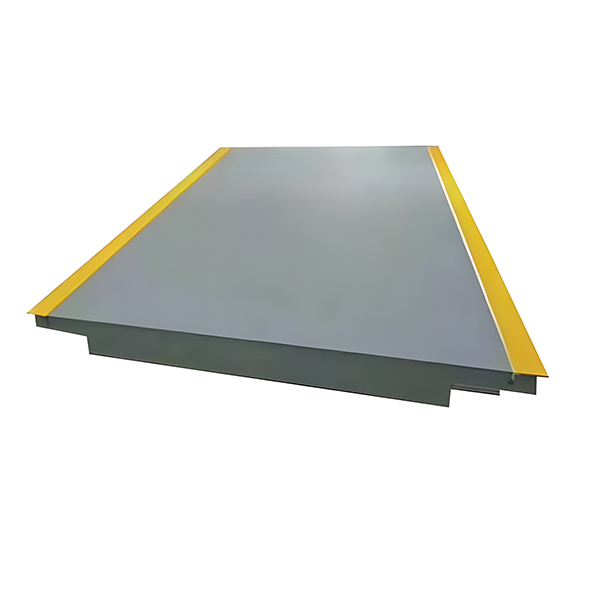

• Steel Scale Platform

Advantages: Cheap and impact-resistant; withstands impacts when hauling scrap steel and gravel.

Weaknesses: Weld joints rust through, scale surface becomes dented (especially in coastal/northern areas affected by de-icing agents); poor maintenance renders it unusable after ten years.

• Concrete Scale Platform

Advantages: Corrosion-resistant; can last over 20 years in chemical plants and salt fields.

Weaknesses: Susceptible to heavy impacts (such as from excavators hitting corners); cracks allow water to seep in and freeze the reinforcing steel.

II. Three Major Killers of Shortened Lifespan

• Excessive Overloading

Taking a scale marked for 100 tons and forcing it to carry 150 tons ▸ Damages the sensors, like a strained back that can no longer function.

• Violent Loading and Unloading

Drivers speeding onto the scale ▸ Impact damages the sensors, more damaging than overloading.

• Worry-free scale maintenance

If the gaps in the scale are clogged with coal ash or frozen ice and not cleaned, the scale will be lifted, and the readings will be erratic and unpredictable.

III. Three life-saving essentials

Regularly remove obstructions: Clean the gaps in the scale weekly (especially after snow). Each cleaning adds another six months to its lifespan.

Regular checkups: Calibrate the scale quarterly: Use standard weights to balance it. A small expense prevents major repairs.

Check the foundation after heavy rain: If the subsidence exceeds the thickness of a fingernail (≈3mm), call for repairs immediately.

Rust prevention is a necessity: Apply anti-rust paint to steel scales annually. Repairing rust that has penetrated the scale is like using a band-aid to treat a broken bone.

IV. Environmental Impact on Lifespan

| Use Scenario | Average Lifespan | Primary Failure Causes |

|---|---|---|

| Logistics Park (Indoor) | 20+ years | Minimal sun/rain exposure; consistent maintenance |

| Mining/Construction Sites | 8–12 years | Abrasive material wear; frequent overloading |

| Ports/Salt Processing | 10–15 years | Accelerated corrosion from saltwater exposure |

V. Scrapping Signals: It's time to replace the scale!

Reading Malfunction: Empty scale displays "0000", loads a vehicle and it changes to "2500", unloads a vehicle and it jumps to "0500"—the sensor is about to fail.

Scale Platform "Hunchback": Visibly dented in the middle or raised corners, creaking when heavy.

Repair is More Expensive Than Buying: Replacing the sensor costs 30% more than a new scale; it's better to just buy a new one.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体