Web Menu

Product Search

Exit Menu

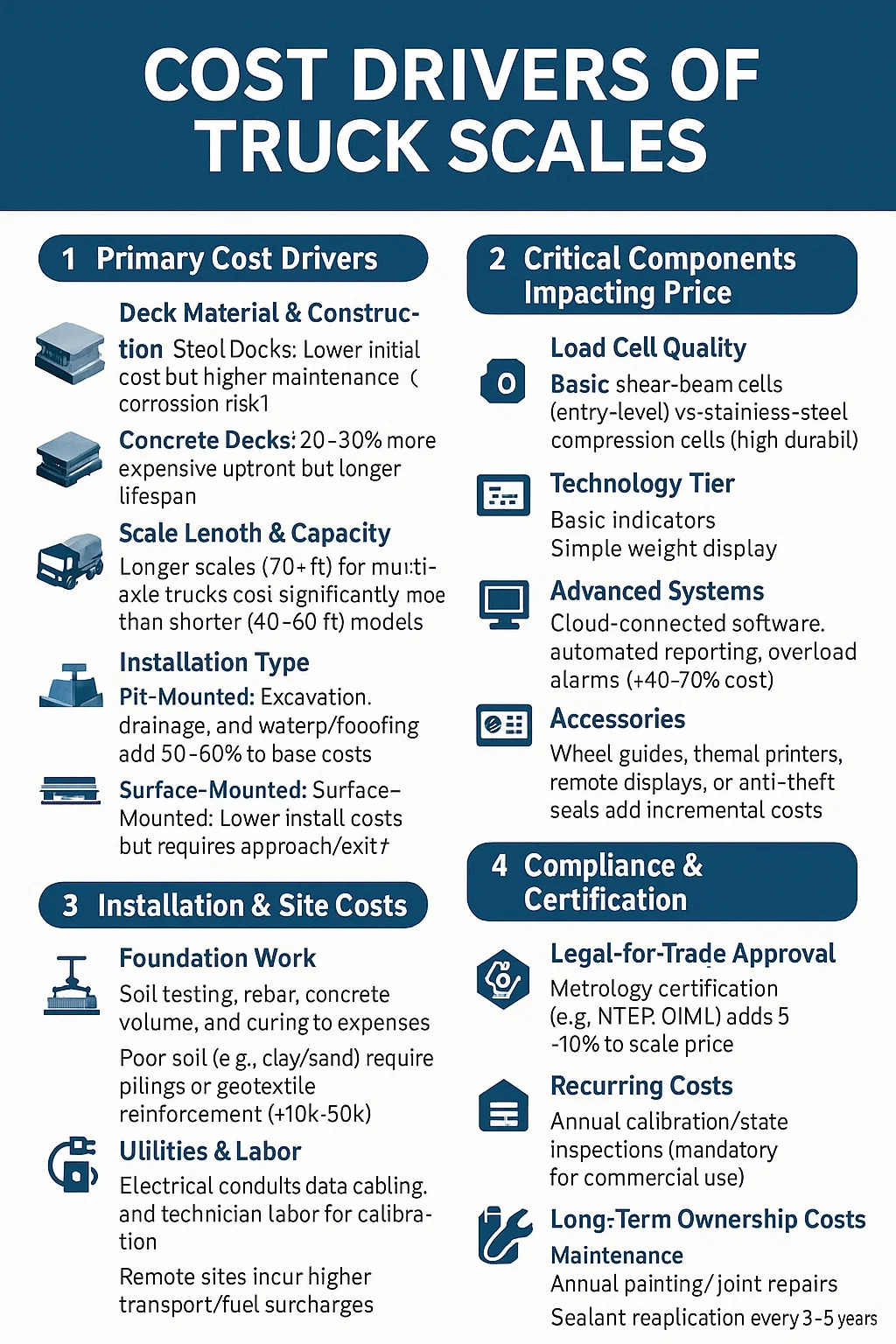

How much does a truck scale cost?

The cost of a truck scale is highly variable and driven by multiple factors. Below is a breakdown of key cost drivers and typical price ranges in industrial contexts:

Content

1. Primary Cost Drivers

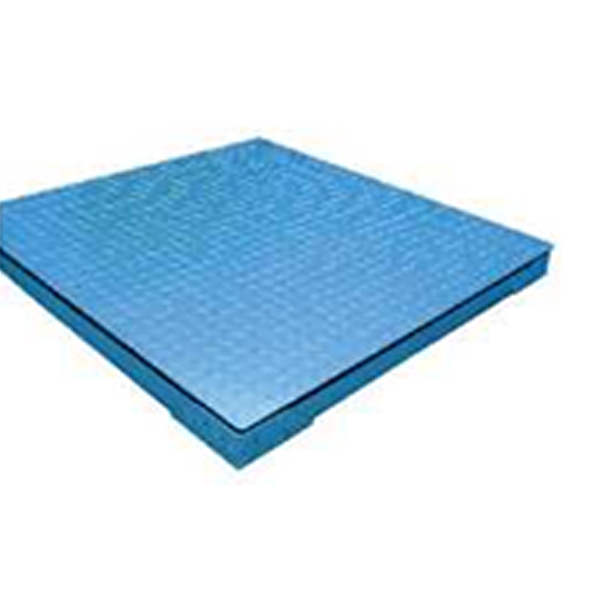

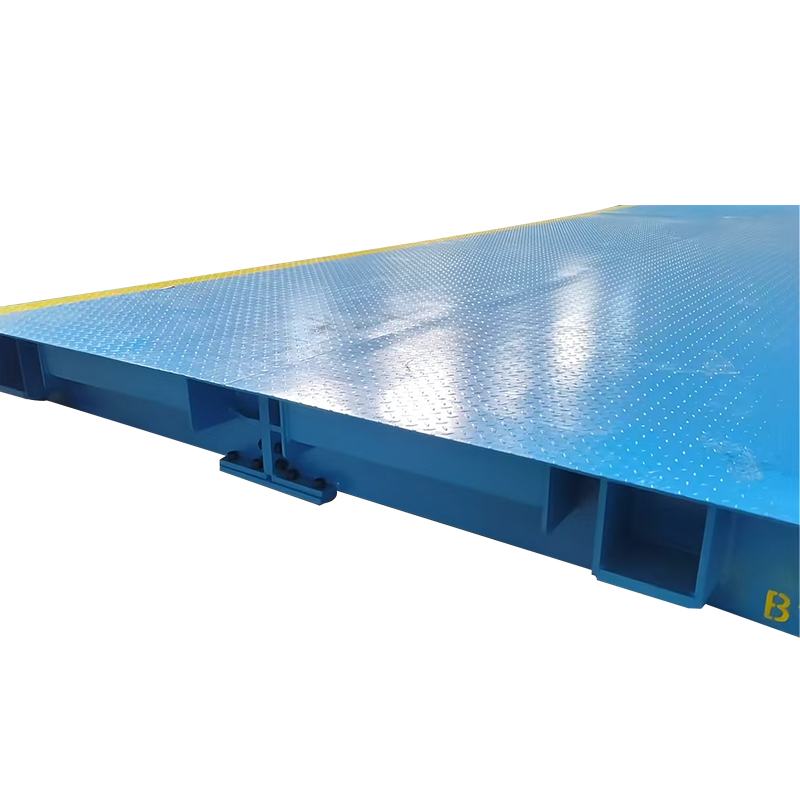

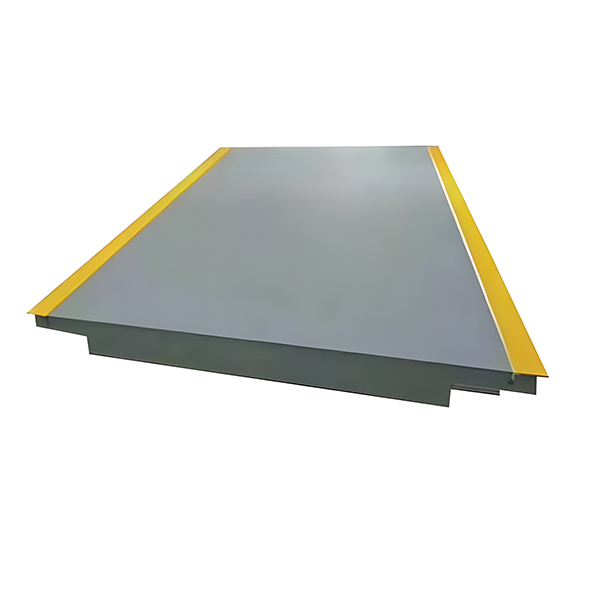

Deck Material & Construction:

Steel Decks: Lower initial cost but higher maintenance (corrosion risk).

Concrete Decks: 20–30% more expensive upfront but longer lifespan.

Scale Length & Capacity:

Longer scales (70+ ft) for multi-axle trucks cost significantly more than shorter (40–60 ft) models.

High-capacity scales (100+ tons) require thicker steel/deeper foundations.

Installation Type:

Pit-Mounted: Excavation, drainage, and waterproofing add 30–50% to base costs.

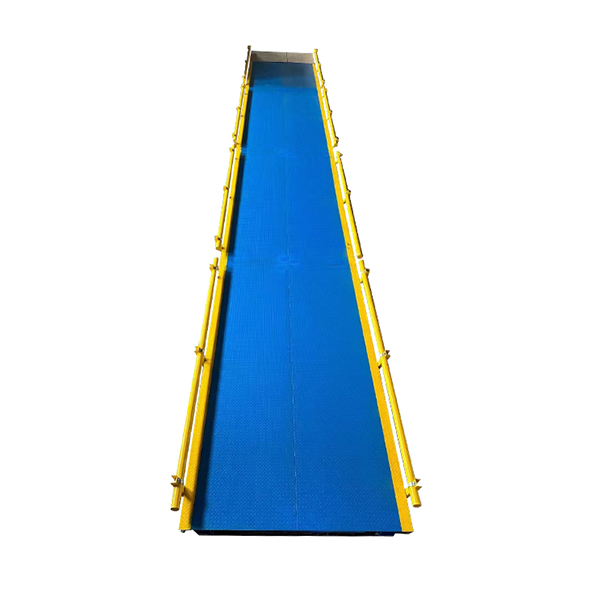

Surface-Mounted: Lower install costs but requires approach/exit ramps.

2. Critical Components Impacting Price

Load Cell Quality:

Basic shear-beam cells (entry-level) vs. stainless-steel compression cells (high durability, +15–25% cost).

Technology Tier:

Basic Indicators: Simple weight display.

Advanced Systems: Cloud-connected software, automated reporting, overload alarms (+40–70% cost).

Accessories:

Wheel guides, thermal printers, remote displays, or anti-theft seals add incremental costs.

3. Installation & Site Costs

Foundation Work:

Soil testing, rebar, concrete volume, and curing time dominate expenses.

Poor soil (e.g., clay/sand) requires pilings or geotextile reinforcement (+10k–50k).

Utilities & Labor:

Electrical conduits, data cabling, and technician labor for calibration.

Remote sites incur higher transport/fuel surcharges.

4. Compliance & Certification

Legal-for-Trade Approval:

Metrology certification (e.g., NTEP, OIML) adds 5–10% to the scale price.

Recurring Costs:

Annual calibration/state inspections (mandatory for commercial use).

5. Long-Term Ownership Costs

Maintenance:

Steel decks: Annual painting/joint repairs.

Concrete decks: Sealant reapplication every 3–5 years.

Repairs:

Load cell replacement (flood/lightning damage).

Foundation crack repairs or deck realignment.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体