Web Menu

Product Search

Exit Menu

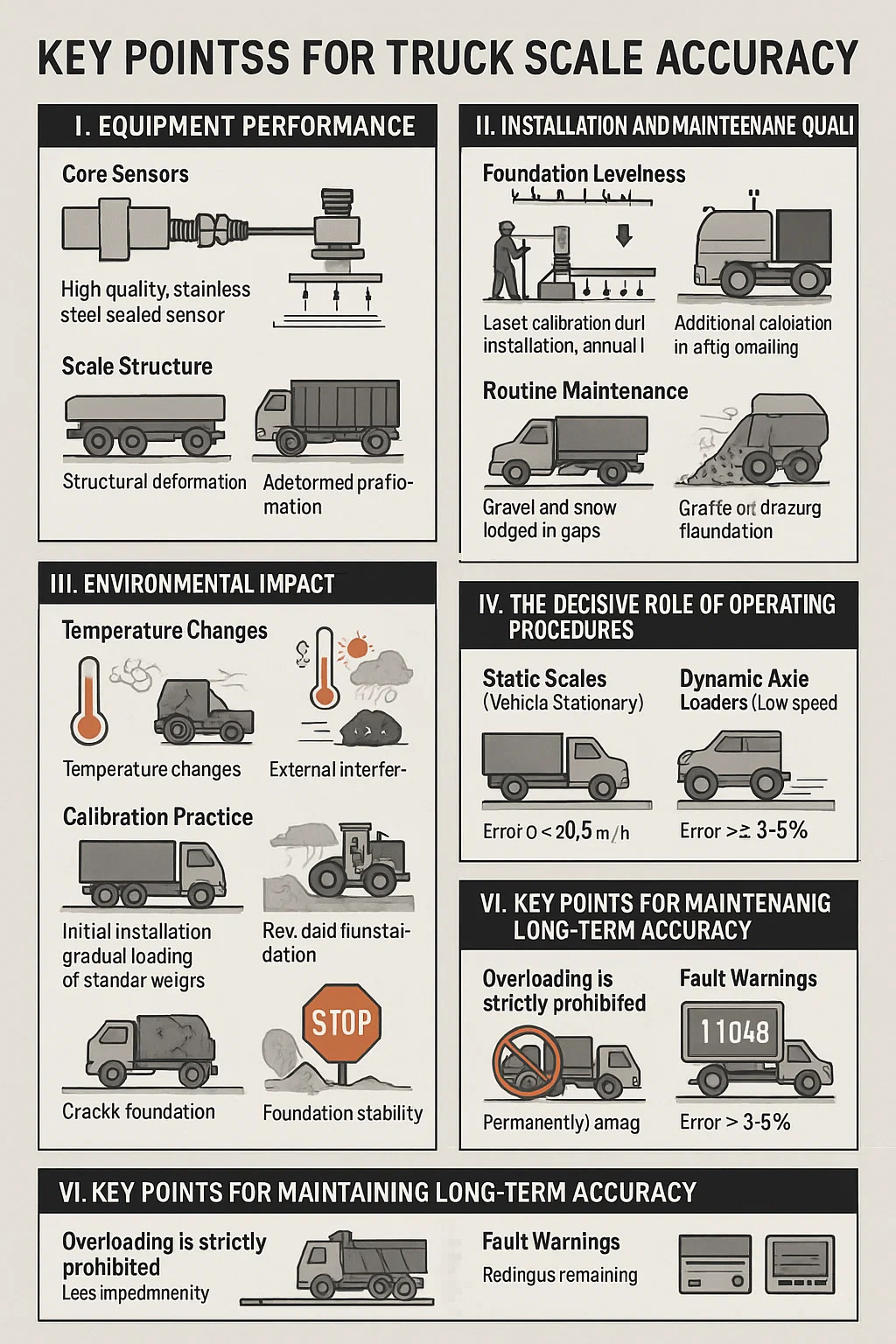

How precise are truck scales?

The accuracy of truck scale is affected by multiple factors, requiring a comprehensive assessment of equipment quality, environmental conditions, and operating procedures during actual use. Here are the key points:

Content

I. Equipment Performance

Core Sensors: High-quality stainless steel sealed sensors are more stable under varying temperature and humidity conditions, and are less prone to drift over long-term use; low-end sensors are easily interfered with, resulting in significant numerical fluctuations.

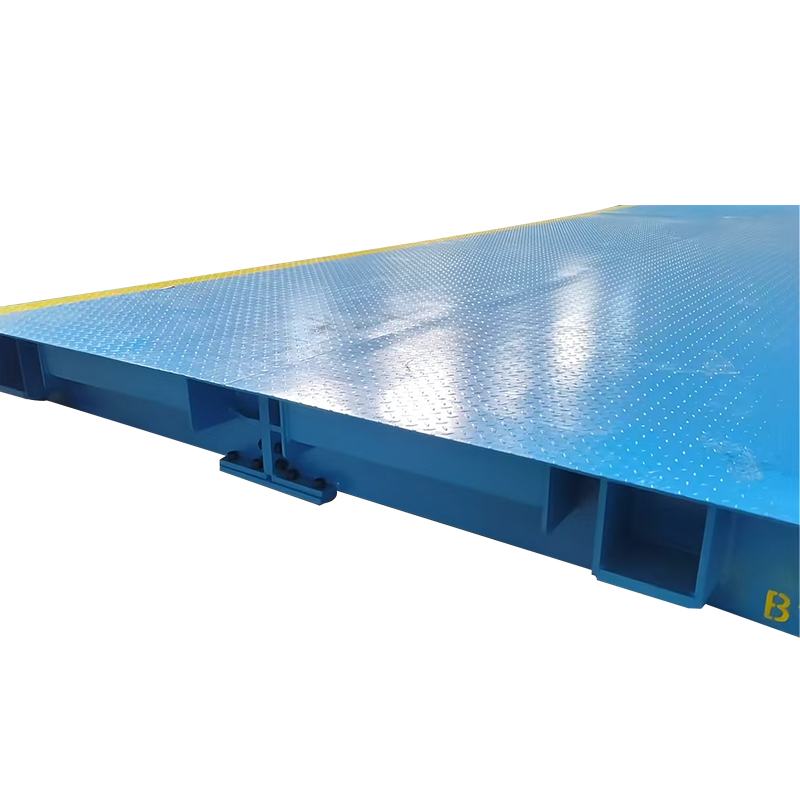

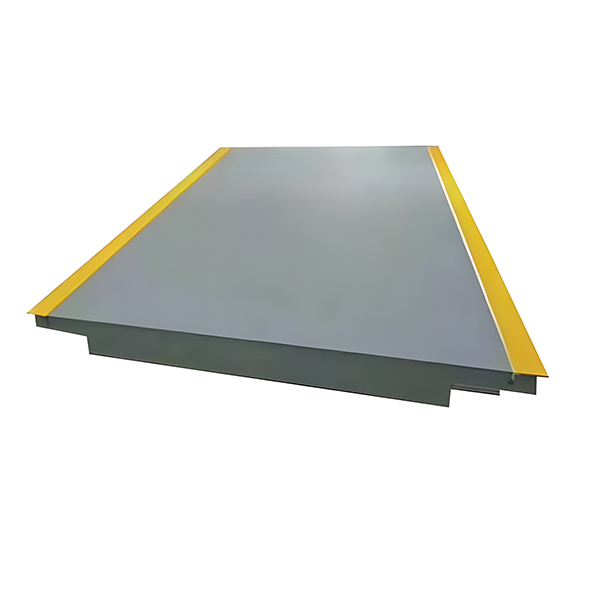

scale Structure: A smoothly welded steel platform or a concrete platform with evenly distributed reinforcing bars ensures uniform weight transfer. Structural deformation (such as long-term overloading) directly reduces accuracy.

II. Installation and Maintenance Quality

Foundation Levelness: A tilted foundation can cause errors in the gravity component. Laser calibration is required during installation, and settlement should be checked annually.

Calibration Practice

Initial Installation: Gradually load standard weights, adjusting the balance at all four corners (avoiding one corner being hundreds of kilograms too high).

Periodic Calibration: Additional calibration is required after high-frequency use or extreme weather events; missed calibrations can lead to cumulative errors.

Routine Maintenance: Gravel and snow stuck in the gaps of the weighing platform can lift the scale, causing hundreds of kilograms of false weight readings; the sensor junction box needs to be protected from rain and corrosion.

III. Environmental Impact

Temperature Changes: Metal contracts in extreme cold and expands in extreme heat. If the equipment lacks temperature compensation, a temperature difference of over 20°C may cause an error of 0.1%.

External Interference: Strong winds pushing vehicles generate lateral forces, or vibrations from nearby machinery are transmitted to the weighing platform, potentially causing readings to fluctuate.

Foundation Stability: Soft soil and sandy areas are prone to settlement when exposed to rain; concrete cracks require immediate cessation of use.

IV. The Decisive Role of Operating Procedures

Vehicle Parking: When wheels touch the edge of the weighing platform, the error can reach 300-500 kilograms.

Sudden braking and impact when entering the weighing platform can cause false readings; maintain a constant speed of ≤5 km/h.

Data Reset: If the empty vehicle is not properly zeroed, or if debris (such as water or snow) remains in the truck bed, all subsequent load data will be distorted.

V. Differences in Technical Types

Static scales (Vehicle Stationary): Compliant products, under standardized operation, can meet trade settlement-level accuracy (e.g., error ≤ 0.1%).

Dynamic Axle Loaders (Low-Speed Weighing): Due to uneven vehicle speed and tire pressure differences, single-axle errors may reach 3-5%, suitable only for pre-inspection.

VI. Key Points for Maintaining Long-Term Accuracy

Overloading is strictly prohibited: A single overload exceeding the limit by 150% may permanently damage the sensor, leading to consistently underweight readings.

Fault Warnings: Irregular reading fluctuations, displaying residual weight after zeroing, and continuous weighing differences for the same vehicle > 0.3% require shutdown and maintenance.

Equipment Upgrade: Mechanical scales used for over 10 years experience rapid accuracy degradation due to component wear; upgrading to digital is recommended.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体