Web Menu

Product Search

Exit Menu

What are the types of weighbridges?

Content

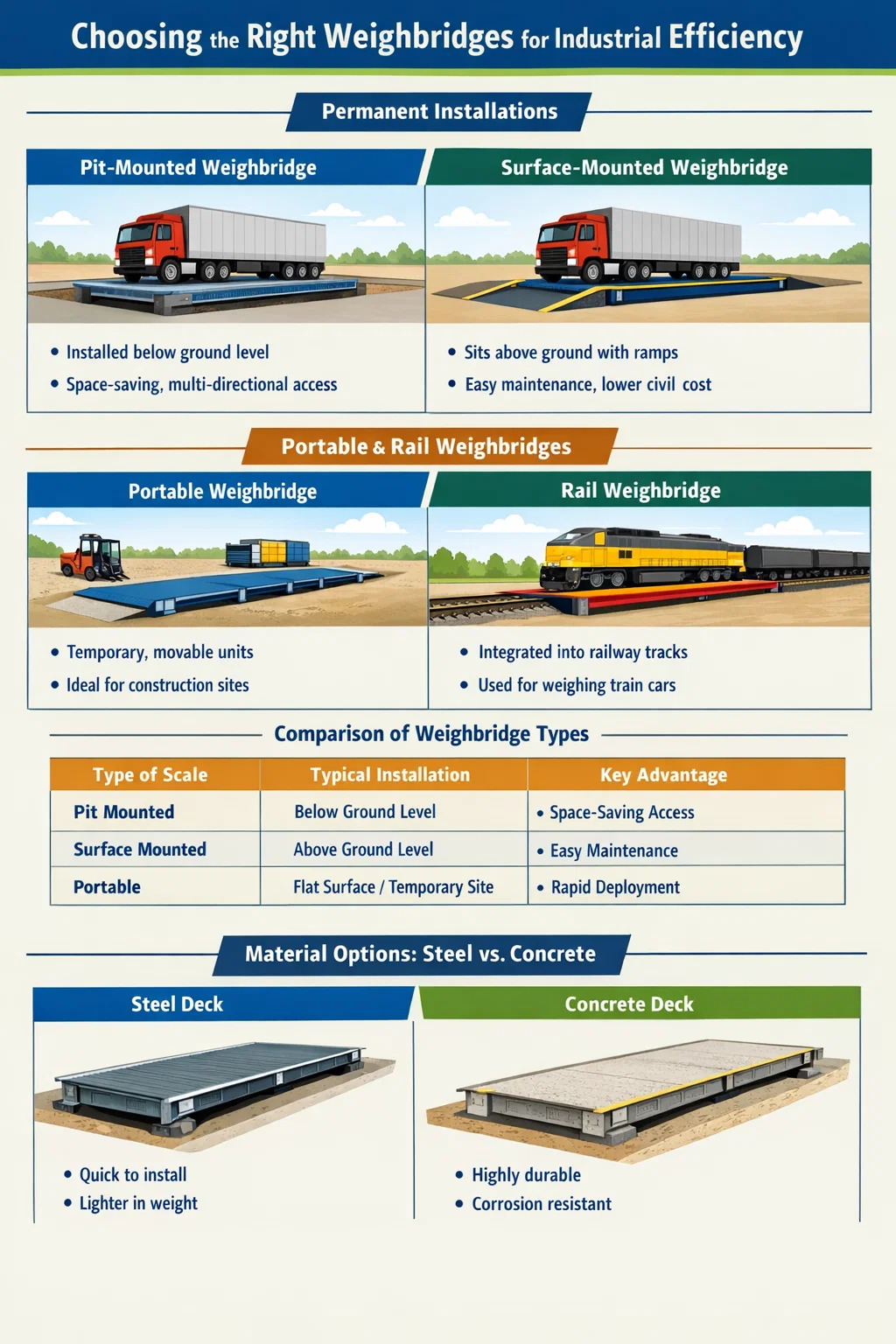

Choosing the Right Weighbridges for Industrial Efficiency

Selecting the correct weighbridge depends primarily on your available space, site conditions, and frequency of use. The primary types are pit-mounted, surface-mounted, and portable weighbridges, each offering distinct advantages for vehicle weight management and cargo verification.

Permanent Installation: Pit vs. Surface Mounted Weighbridges

Most industrial facilities opt for permanent structures due to their high durability and accuracy. The choice between a pit and a surface mount usually comes down to "space versus site preparation cost."

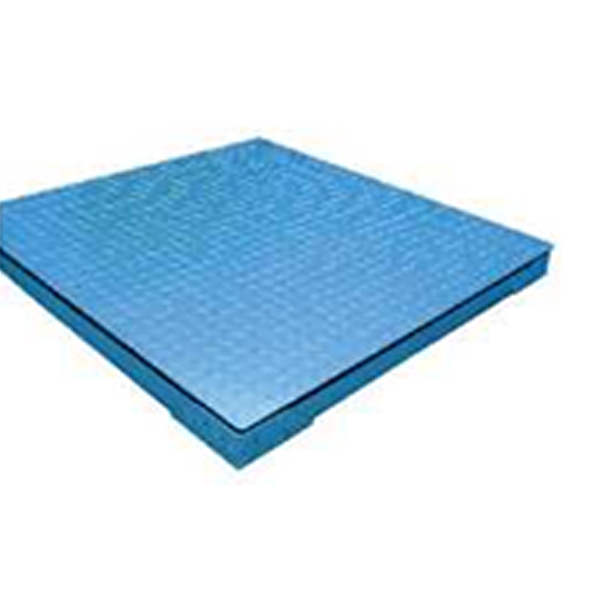

Pit-Mounted Weighbridges

These units are installed within an excavated pit, making the weighing platform flush with the surrounding ground. This design is ideal for sites where space is at a premium, as vehicles can approach from any angle without needing ramps.

- Ideal for high-traffic areas where vehicle maneuverability is essential.

- Requires a comprehensive drainage system to protect load cells from water damage.

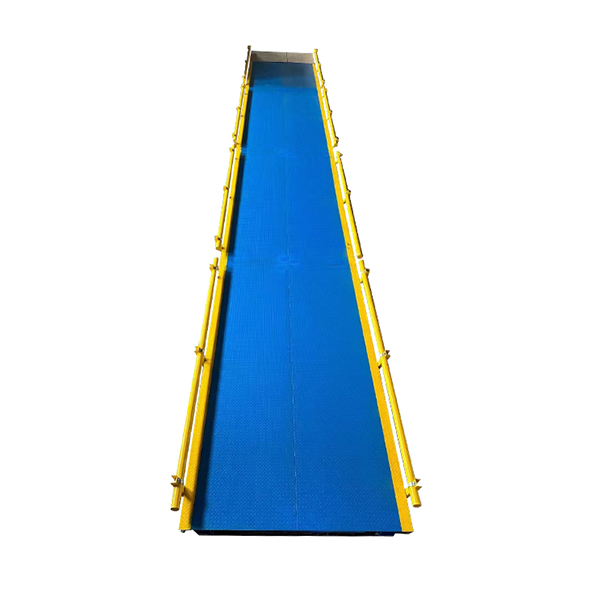

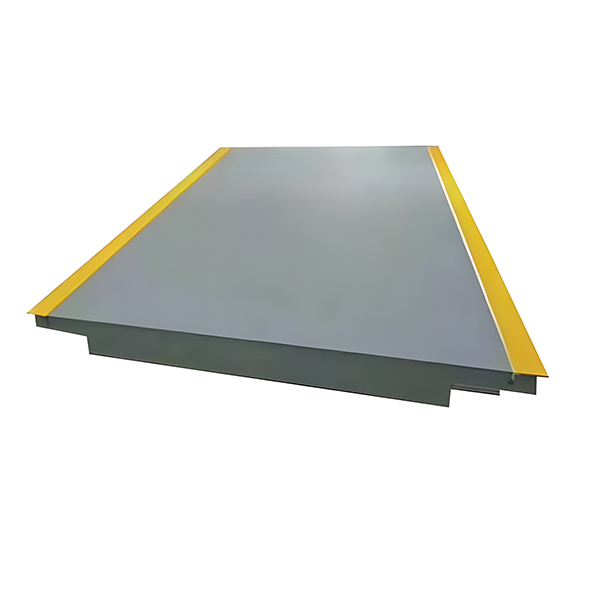

Surface-Mounted Weighbridges

As the name suggests, the platform sits on top of the ground. Vehicles access the scale via on/off ramps. This is often the most cost-effective permanent solution because it avoids heavy excavation work.

- Easier to maintain and clean as the components are accessible above ground.

- Requires significant clearance space for the entry and exit ramps.

Comparison of Core Weighbridge Types

To help visualize the differences in application and construction, the following table summarizes the three main categories used in modern logistics.

| Type of Scale | Typical Installation | Key Advantage |

|---|---|---|

| Pit Mounted | Below Ground Level | Space-saving / Multi-directional access |

| Surface Mounted | Above Ground Level | Easy maintenance / Lower civil costs |

| Portable | Flat Surface/Temporary Site | Mobility / Rapid deployment |

Specialized Weighbridges: Portable and Rail Scales

Beyond traditional permanent truck scales, some industries require flexibility or specialized measurement for rail transport.

Portable Weighbridges

Portable weighbridges are modular units designed for short-term projects, such as construction sites or logging operations. These can be set up on any level, firm surface and relocated using a crane or forklift.

Rail Weighbridges

These are integrated into the railway tracks to weigh train cars either while stationary or while moving (in-motion weighing). They are essential for mining and bulk grain transport where volume is measured by the trainload.

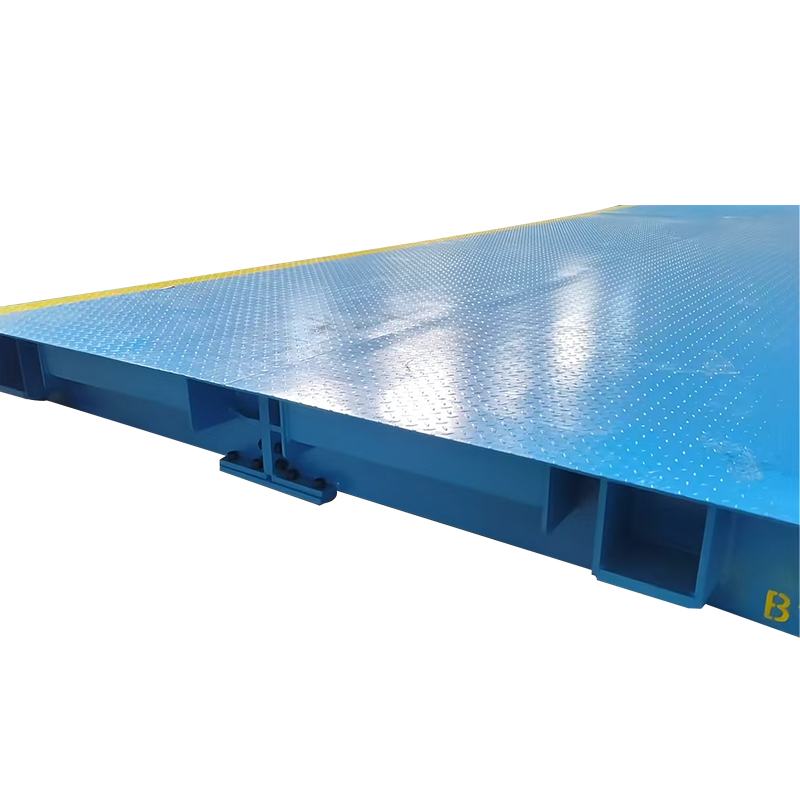

Material Options: Steel vs. Concrete

The deck of the weighbridge is typically made of either steel or concrete. This choice affects both the initial cost and the long-term durability of the scale.

- Steel Decks: Lighter and easier to install. A standard steel deck can be operational within one day of delivery.

- Concrete Decks: Extremely durable and less prone to rust. While they require a curing period of 21 to 28 days, they often outlast steel in harsh chemical or coastal environments.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体