Web Menu

Product Search

Exit Menu

How does a weighbridge work? Technical core principles explained.

A weighbridge is like a giant scale installed on the ground. Its main job is to tell people how much a large truck weighs after it's loaded with goods.

Content

Here's an explanation of how a weighbridge works:

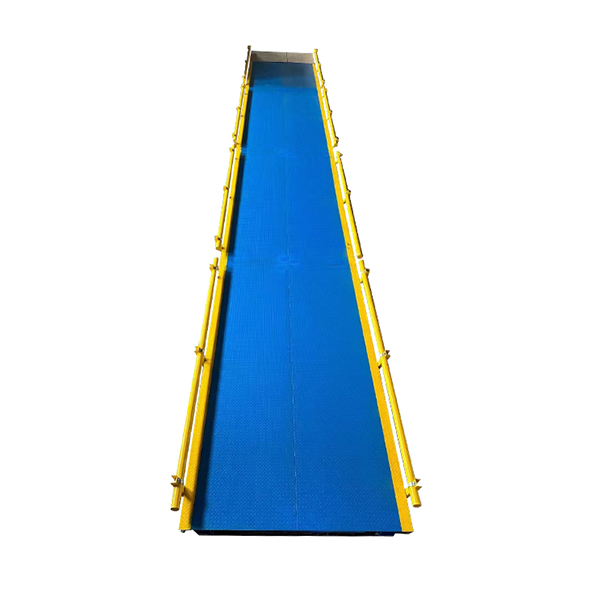

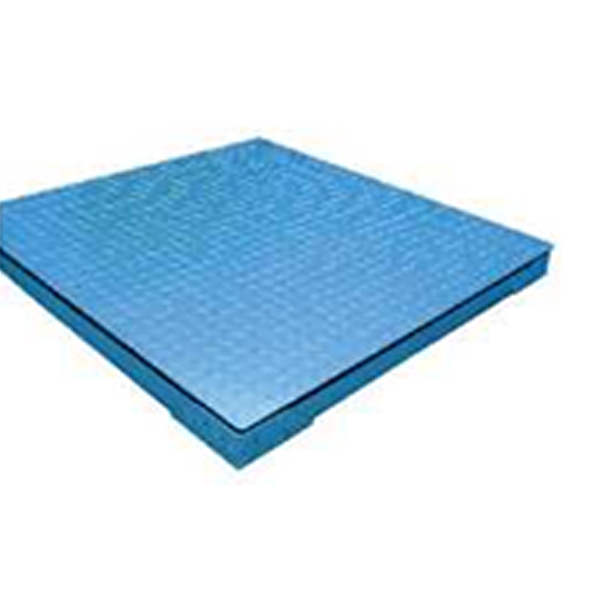

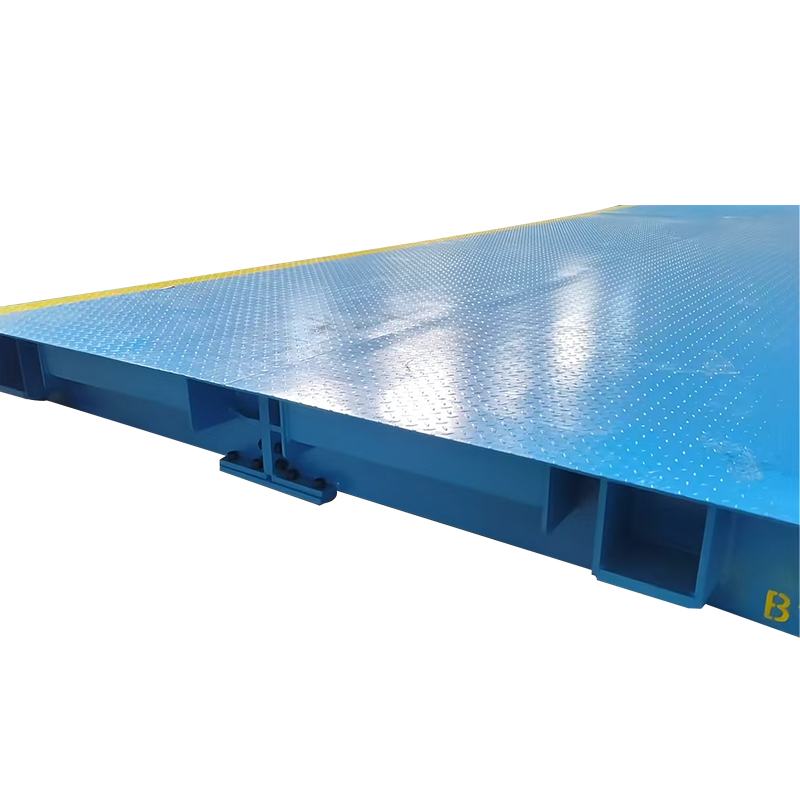

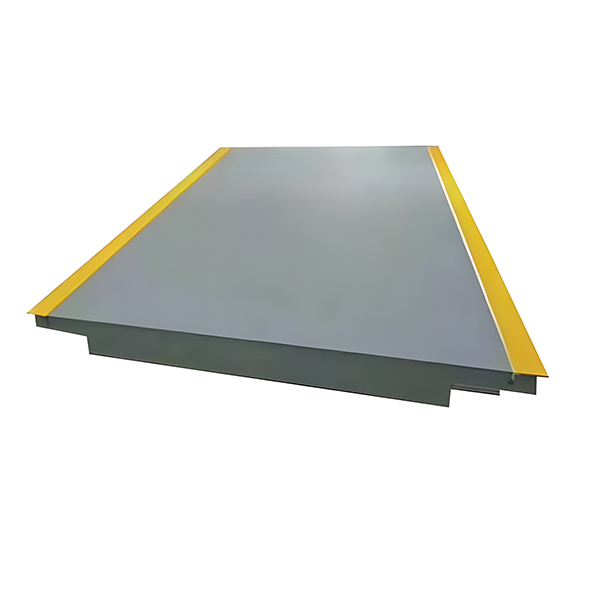

1. Sturdy Load-Bearing Platform

First, you see a huge flat surface – this is the weighbridge platform. It's usually made of heavy steel plates or concrete, laid flat on the ground (or in a pit). This platform must be very strong because its job is to support trucks and cargo weighing tens or even hundreds of tons.

2. Hidden "Sensory Nerves"

Beneath the large platform, there are several key components called load cells. You can think of them as pressure sensors.

When a truck drives onto the weighbridge, the truck's weight presses vertically down on the platform.

The platform then transmits this pressure to the sensors underneath.

The sensors, upon feeling the pressure, generate a weak electrical signal. The greater the pressure, the stronger the signal.

3. Signal Collection and Transmission

The signals from each sensor are collected in a junction box. The junction box's function is to combine the pressure signals from different locations (such as the front, rear, left wheels, and right wheels) to ensure that the final weight is accurate regardless of where the truck is positioned on the platform.

4. Turning into Visible Numbers

The combined signal is transmitted via cable to a control room's instrument panel or computer monitor.

The electronic system in the instrument panel "translates" the complex electrical signals into weight numbers that everyone can understand.

The operator, sitting in the control room, can see the total weight of the truck in real time.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体