Web Menu

Product Search

Exit Menu

How much does it cost to put in a truck scale?

The cost of installing a truck scale is like renovating a house – materials, labor, and hidden expenses are all unavoidable.

Content

I. The Scale Platform Itself: Steel or Concrete?

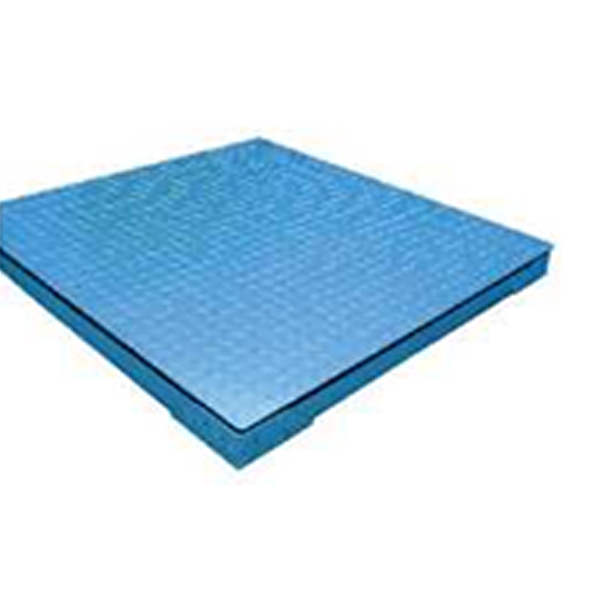

• Steel Platform

Advantages: Cheaper, like buying a bare-bones house, you can paint it yourself later for rust prevention.

Disadvantages: Easily corroded by de-icing agents in the north and salt spray by the sea; repair costs after 10 years could buy half a new scale.

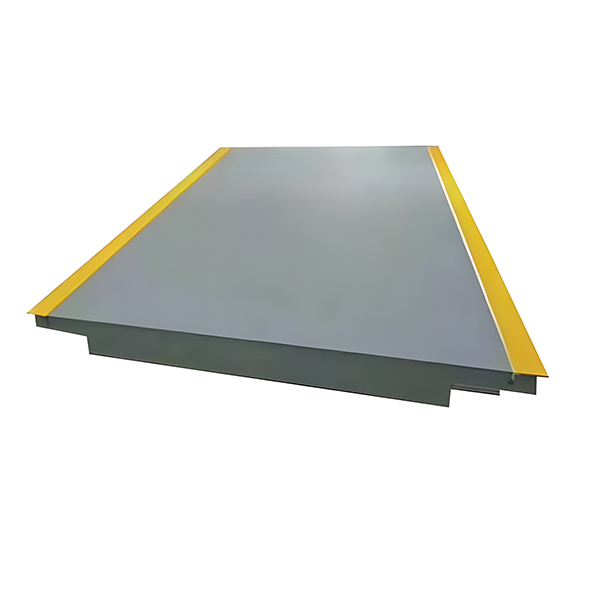

• Concrete Platform

Advantages: Durable, can be used in chemical plants for 20 years without rusting or cracking.

Disadvantages: 30% more expensive than steel, but saves on annual painting costs.

• Money-Saving Tip:

Used scale platforms are half price, but beware of internal damage (overloaded scales are like accident cars, the repairs never end).

II. Foundation Construction: The pit for burying the scale is the biggest money pit.

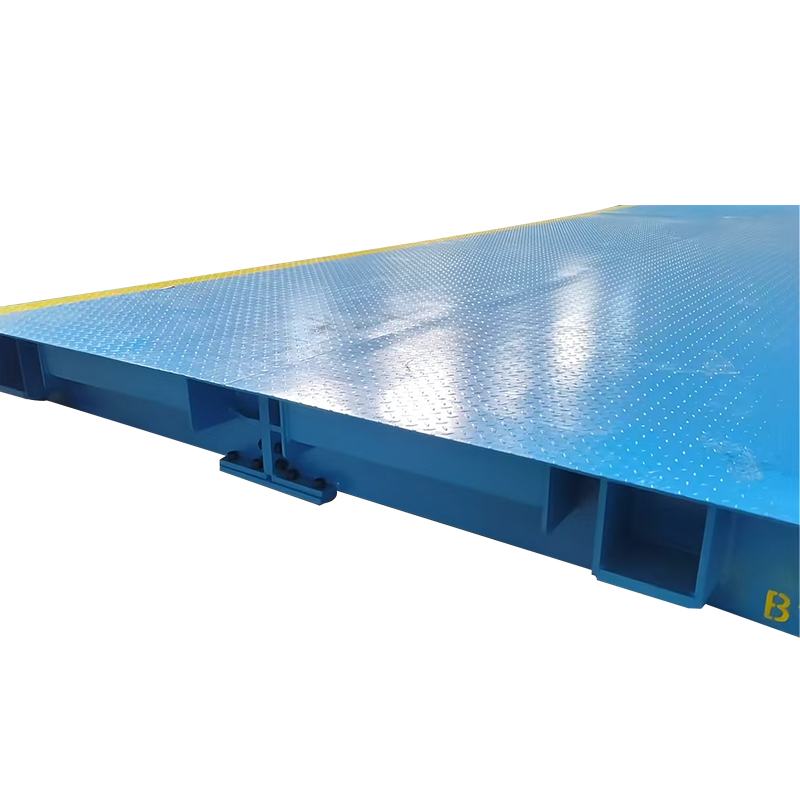

• Pit Installation

Requires digging a 2-meter deep pit, waterproofing + drainage ditches; the cost is enough to buy a new scale. → Suitable for highway toll stations (high traffic, prone to vibration).

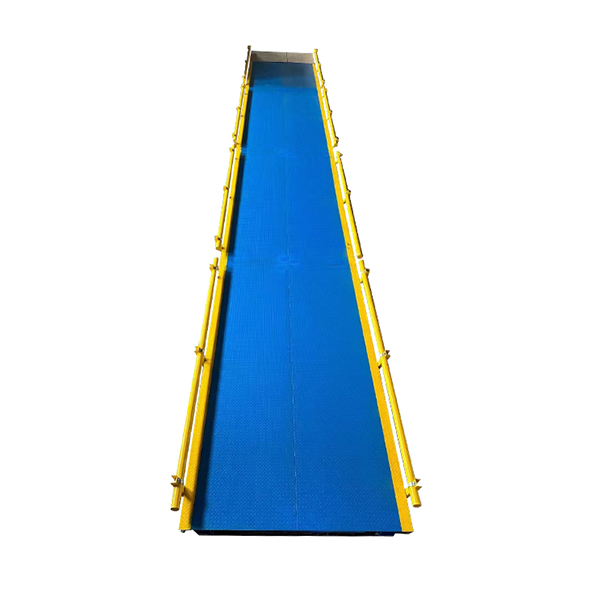

• Ground Installation

No pit digging required, but requires building ramp bridges (takes up space, inconvenient for forklifts). → Commonly used in logistics warehouses, construction costs are halved.

• Essential Projects:

Geological Survey: Soft soil and sandy ground require piling for reinforcement, otherwise the scale platform will become a leaning tower in three years.

Concrete Grade: Using C30 concrete to cut corners? Overloaded trucks will crack it after a few passes; C40 or higher is necessary.

III. Hidden Costs: Sneaky expenses that drain your wallet

• Transportation and Lifting Costs

A 30-ton scale platform requires a heavy-duty crane; road height restrictions in villages may require detours – transportation costs might be more expensive than the scale itself.

• Electrical and Signal Cables

Running dedicated lines from the weighbridge room (for lightning protection), the cost of the wires is enough to buy an electric tricycle.

• Official Certification Fees

Annual inspection and initial inspection fees from the metrology bureau (you can't do business without paying), equivalent to buying health insurance for the scale.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体