Web Menu

Product Search

Exit Menu

How much does a weighbridge cost? (Price Guide)

How much does a weighbridge (truck scale) actually cost? This isn't a simple fixed price, as it's more like an engineering project than a product delivered by courier. The price difference mainly stems from your specific needs and installation environment.

Content

Here are several key factors affecting the price of a weighbridge:

1. Choice of Material

This is a significant part of the cost.

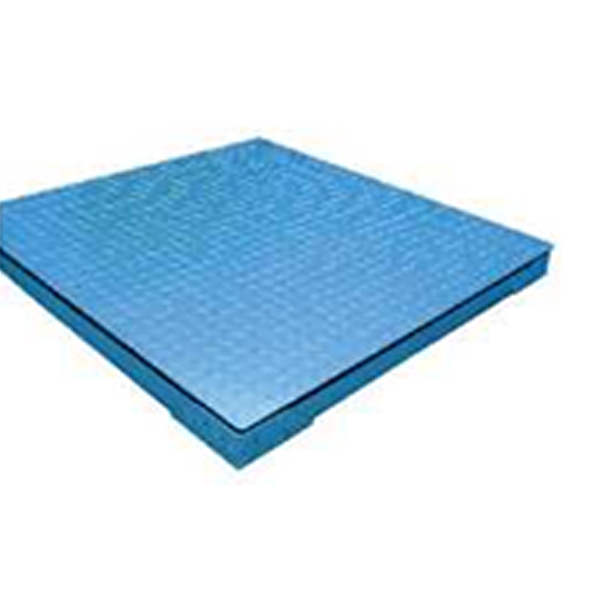

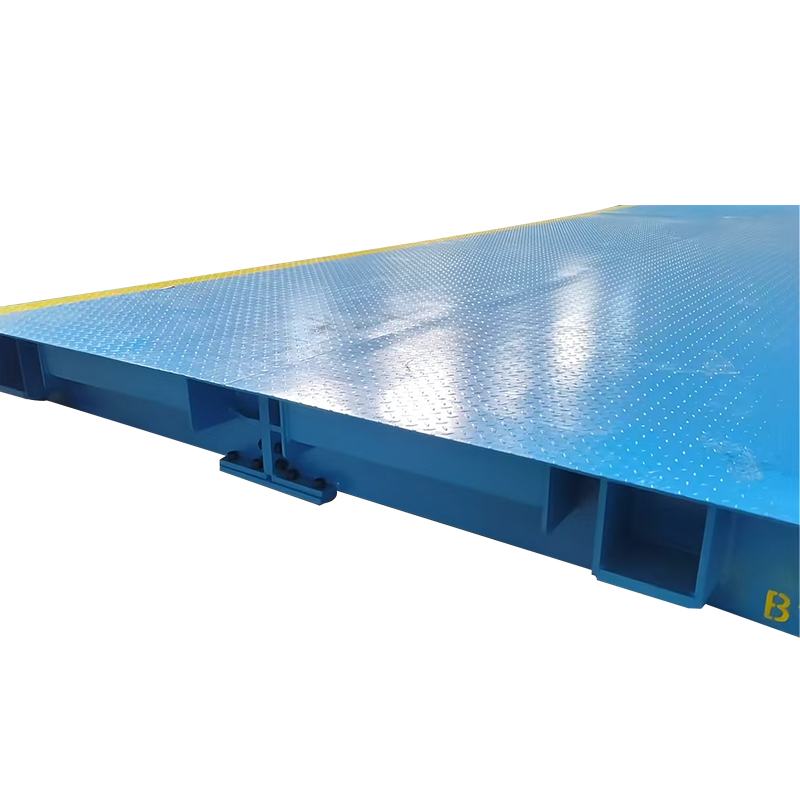

All-steel structure: Usually welded from heavy-duty channel steel and steel plates. Its advantages include fast installation, and it can be disassembled and moved if the factory relocates.

Concrete platform: Although the construction period is longer and requires on-site pouring, it is more durable in humid or corrosive environments, and its lifespan is often longer than that of all-steel structures.

2. Size and Load Capacity

Just like buying a car, the larger and stronger it is, the more expensive it will be.

Length: Common lengths include 9 meters, 12 meters, 16 meters, and even 18 meters. You need to decide based on the longest vehicle you usually weigh (such as trailers or extended trucks).

Tonnage: 50 tons, 80 tons, 100 tons, etc. The stronger the load capacity, the thicker the steel required underneath, and the better the sensors needed.

3. Installation Method (Foundation Engineering)

This part of the cost is often overlooked by first-time buyers, but it is actually very important.

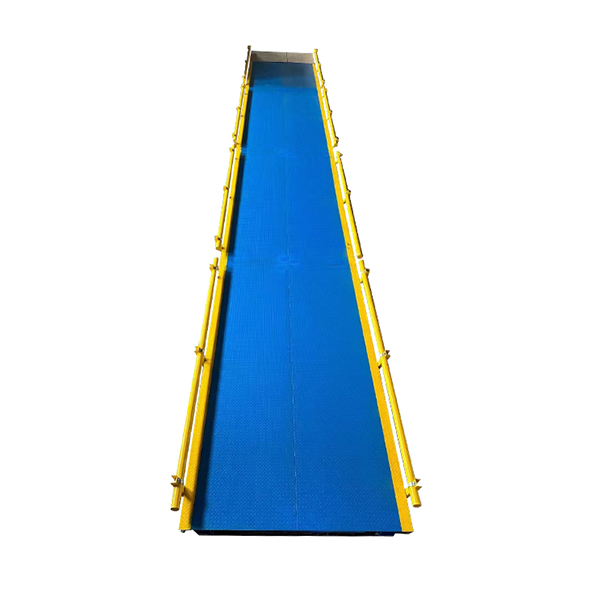

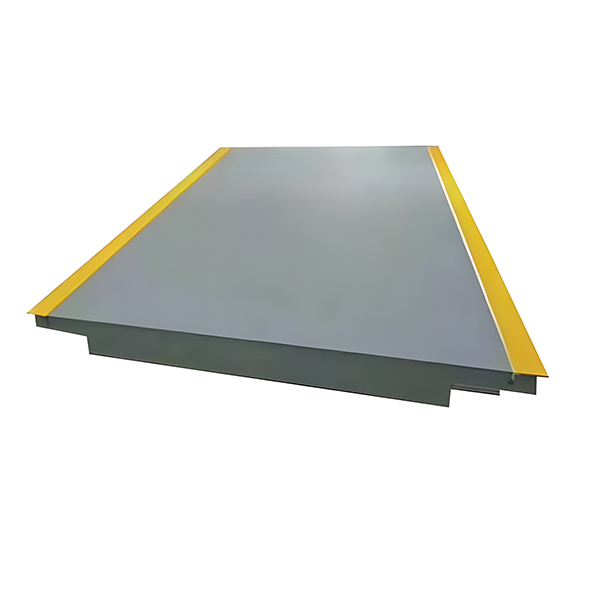

Above-ground type (no pit): Installed directly on the ground, requiring ramps on both sides. This method has good drainage, is easy to maintain, and the foundation construction is relatively inexpensive.

In-ground type (with pit): The scale surface is flush with the ground, saving space and making it convenient for trucks to turn. However, it requires excavating a pit and building a complex drainage system, which significantly increases the foundation cost.

4. Core Precision Components

Although it looks like a large piece of steel, the internal electronic components determine its accuracy.

Sensors: Do you need ordinary or high-precision sensors? Are they domestically produced or imported brands?

Display instrument: Whether you need to connect to a computer, print weigh slips, or require special functions such as lightning protection and waterproofing will affect the final price.

5. Other Hidden Costs

In addition to the cost of the machine itself, you also need to budget for:

Shipping costs: The transportation cost of such a large and heavy item is not insignificant. Lifting and installation fee: A large crane is required for installation.

Commissioning and calibration: After installation, the equipment must be repeatedly tested and calibrated using standard weights to ensure that the readings are valid and accurate.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体