Web Menu

Product Search

Exit Menu

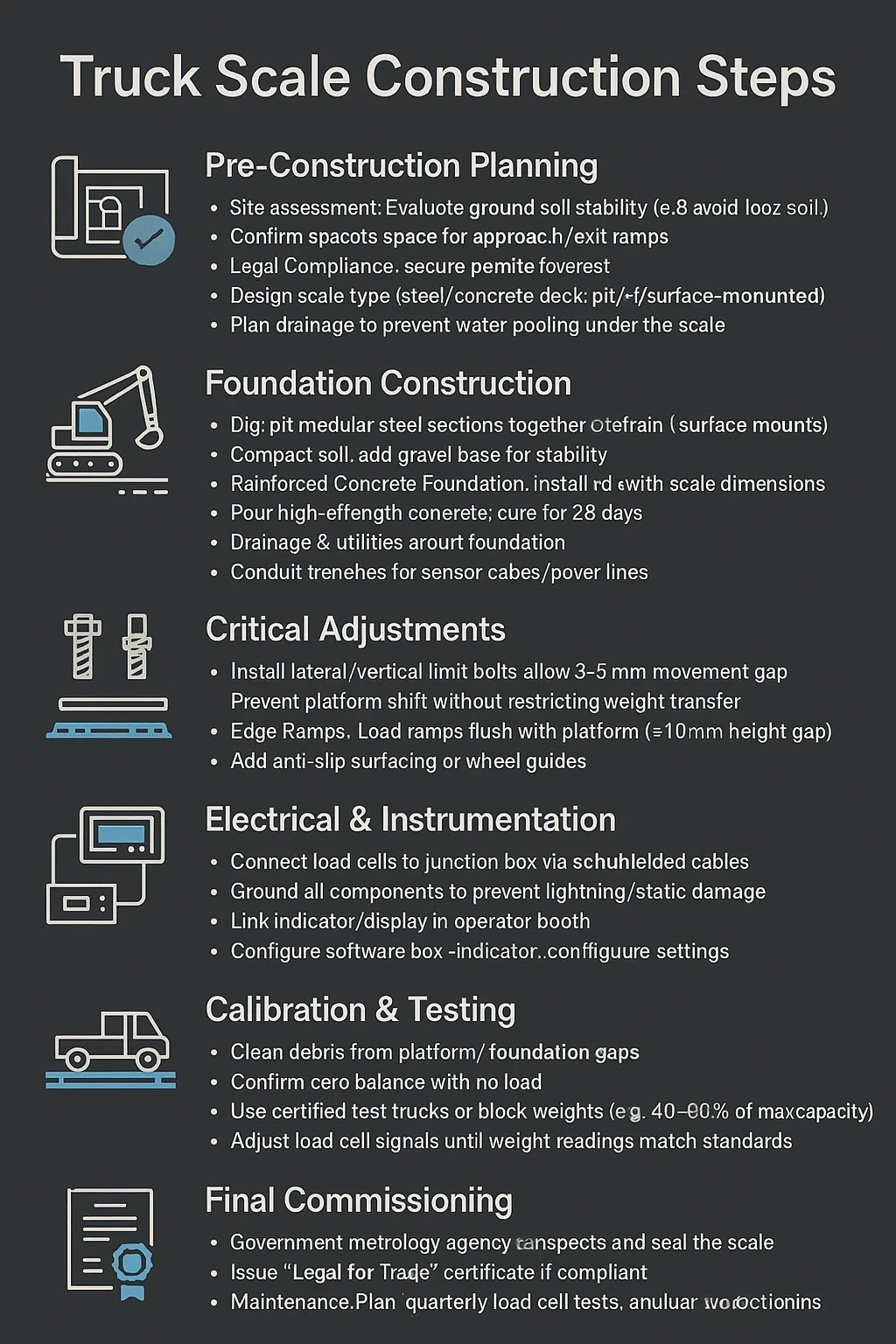

How to build a truck scale?

Building a truck scale requires meticulous planning, specialized expertise, and strict adherence to engineering and safety standards. Below is a step-by-step breakdown of the process:

1. Pre-Construction Planning

Site Assessment:

Evaluate ground soil stability (e.g., avoid flood zones or loose soil).

Confirm adequate space for approach/exit ramps (≥ 30-meter straight lanes).

Legal Compliance:

Secure permits (zoning, environmental, construction).

Verify local metrology regulations for trade-approved scales.

Design Specifications:

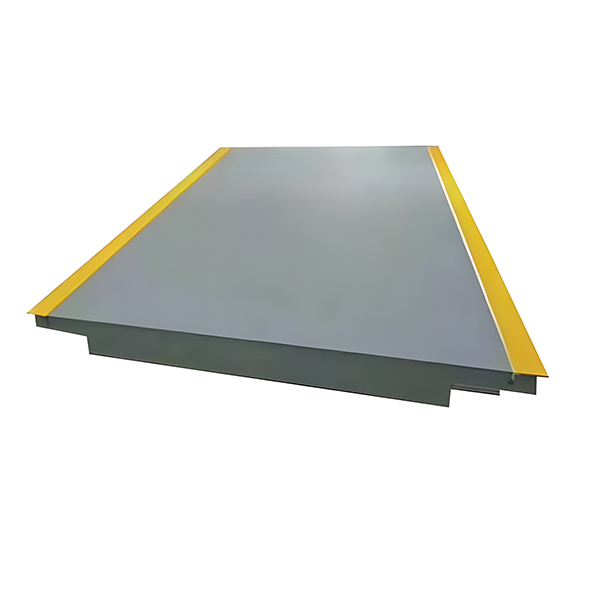

Choose scale type (steel/concrete deck; pit/surface-mounted).

Determine capacity (e.g., 60t, 100t) based on truck traffic.

Plan drainage to prevent water pooling under the scale.

2. Foundation Construction

Excavation & Groundwork:

Dig pit (for pit-mounted scales) or level terrain (surface mounts).

Compact soil; add gravel base for stability.

Reinforced Concrete Foundation:

Install rebar grids and anchor bolts aligned with scale dimensions.

Pour high-strength concrete; cure for 28 days (critical for load-bearing).

Drainage & Utilities:

Embed drain pipes around foundation.

Conduit trenches for sensor cables/power lines.

3. Scale Platform Installation

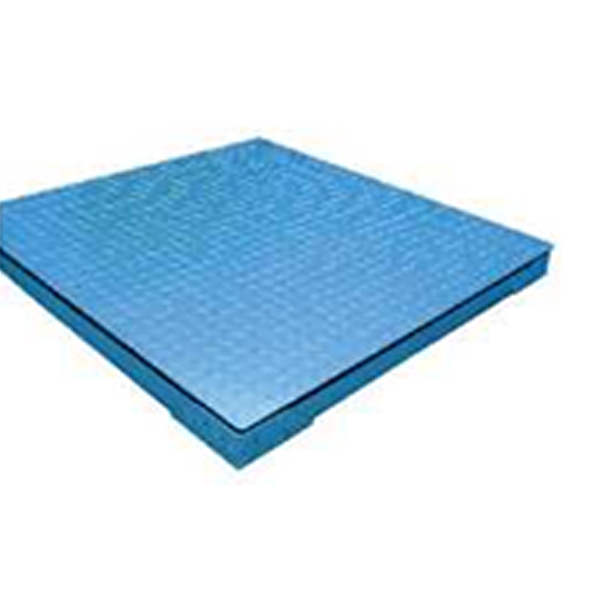

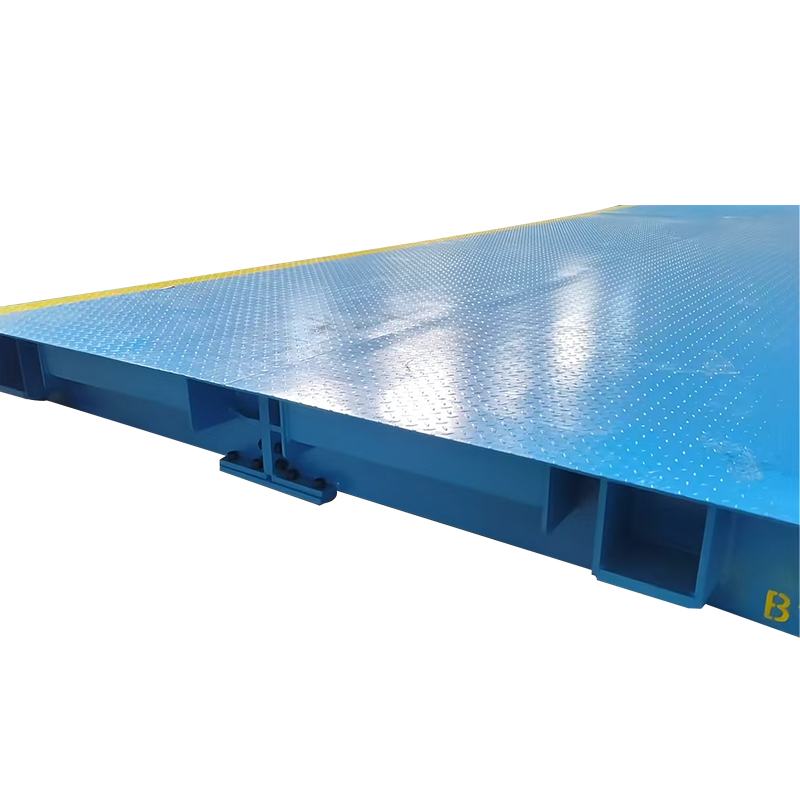

Structural Assembly:

Bolt modular steel sections together on-site (requires crane).

For concrete decks: Cast segments off-site, transport, and join.

Load Cell Placement:

Position load cells on foundation pedestals (ensure level alignment).

Shim cells to compensate for minor unevenness.

Platform Mounting:

Lower platform onto load cells; verify no obstructions touch foundations.

Secure with anchor bolts.

4. Critical Adjustments

Limiters & Restraints:

Install lateral/vertical limit bolts (allow 3–5mm movement gap).

Prevents platform shift without restricting weight transfer.

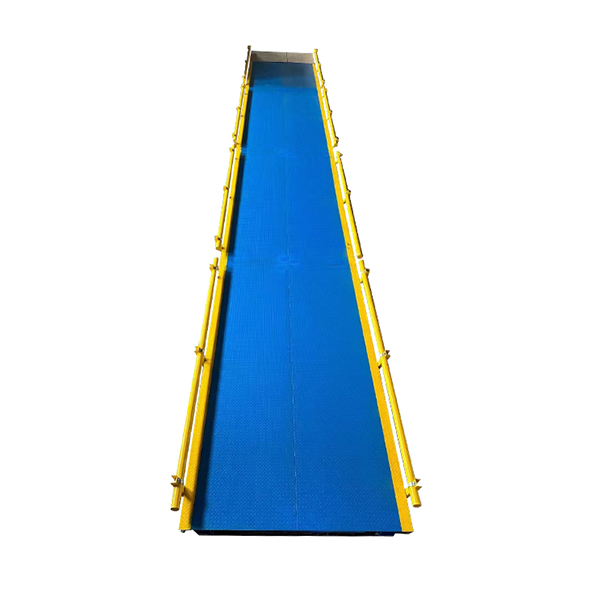

Edge Ramps & Safety:

Weld approach/exit ramps flush with platform (≤10mm height gap).

Add anti-slip surfacing or wheel guides.

5. Electrical & Instrumentation

Wiring:

Connect load cells to junction box via shielded cables.

Ground all components to prevent lightning/static damage.

Instrument Setup:

Mount indicator/display in operator booth.

Link junction box to indicator; configure software settings.

6. Calibration & Testing

Pre-Test Checks:

Clean debris from platform/foundation gaps.

Confirm zero balance with no load.

Legal Calibration:

Use certified test trucks or block weights (e.g., 40–80% of max capacity).

Adjust load cell signals until weight readings match standards.

Dynamic Validation:

Test trucks drive on/off at varying speeds to check stability.

7. Final Commissioning

Authority Approval:

Government metrology agency inspects and seals the scale.

Issue "Legal-for-Trade" certificate if compliant.

Operator Training:

Train staff on weighing protocols, basic diagnostics, and daily cleaning.

Maintenance Plan:

Schedule quarterly load cell tests, annual foundation inspections.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体