Web Menu

Product Search

Exit Menu

What are the uses of a weighbridge?

Content

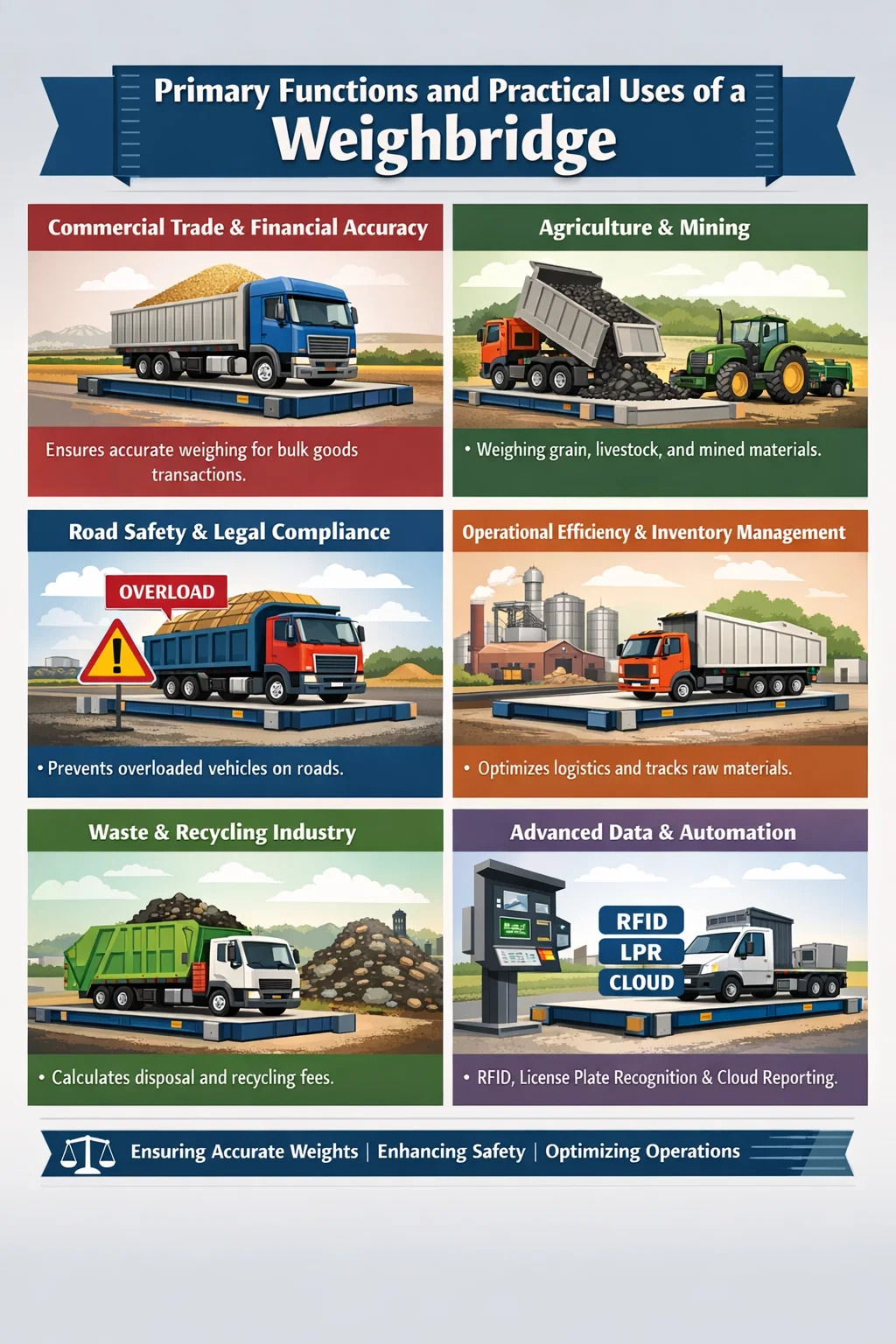

Primary Functions and Practical Uses of a Weighbridge

A weighbridge is an indispensable tool for modern industry, primarily used to accurately measure the weight of large vehicles and their payloads. Its main purposes include ensuring fair commercial transactions through precise weight data, maintaining road safety by preventing vehicle overloading, and optimizing logistics management. By providing a "net weight" calculation—subtracting the empty vehicle's weight from its loaded weight—businesses can quantify bulk materials with extreme precision.

Commercial Trade and Financial Accuracy

In industries where goods are sold by mass, the weighbridge serves as the ultimate arbiter of value. For sectors dealing in bulk commodities, volume-based estimates are often inaccurate and lead to financial discrepancies. Using a certified scale ensures that every ton of material leaving or entering a facility is accounted for.

Agriculture and Mining Applications

In the agricultural sector, farmers use weighbridges to measure grain, hay, and livestock. For instance, when a truck delivers 30 tons of wheat to a silo, a discrepancy of just 1% could mean hundreds of dollars in lost revenue. Similarly, in mining, these scales measure the raw output of coal, iron ore, or precious minerals directly from the pit to the processing plant.

- Ensuring accurate invoicing based on verified weight tickets.

- Reducing "shrinkage" or unauthorized removal of materials during transit.

- Complying with "Trade Approved" regulations for commercial weighing.

Ensuring Road Safety and Legal Compliance

Overloaded vehicles are a major hazard on public infrastructure. A weighbridge acts as a critical checkpoint to ensure that trucks do not exceed the legal Gross Vehicle Mass (GVM). This is not just about avoiding fines; it is about the structural integrity of the vehicle and the road.

Infrastructure Protection

Roads and bridges are engineered to withstand specific weight limits. Excessive weight causes accelerated wear and tear, leading to potholes and structural failure. Transport authorities use weighbridges to enforce these limits. For a fleet operator, checking weights before a vehicle hits the highway prevents costly legal penalties and potential license suspensions.

| Risk Factor | Impact of Overloading | Weighbridge Role |

|---|---|---|

| Braking Distance | Significantly increased; risk of failure | Verifies safe operating weight |

| Tire Wear | Frequent blowouts and rapid degradation | Prevents excessive axle pressure |

| Road Damage | Cracking and subsidence of asphalt | Ensures compliance with axle limits |

Operational Efficiency and Inventory Management

Beyond external trade, weighbridges are essential for internal inventory tracking. In large manufacturing plants or chemical facilities, knowing exactly how much raw material has arrived is vital for production scheduling.

Logistics Optimization

Fleet managers use weight data to optimize fuel consumption. A truck that is under-loaded is just as inefficient as one that is over-loaded, as it increases the number of trips required to move a set amount of cargo. By utilizing the weighbridge to ensure every vehicle is at its optimum legal capacity, companies can reduce fuel costs and carbon emissions.

Environmental and Waste Management Services

In the waste and recycling industry, the weighbridge is the primary method for calculating disposal fees (tipping fees). Since landfills often charge based on weight to encourage recycling, accurate data is necessary for both the facility and the waste hauler.

Recycling centers use weighbridges to sort and value different materials. A truck carrying scrap metal will have its weight recorded upon entry; after dumping the load, the empty truck is weighed again. This precise measurement allows the center to pay the supplier correctly for the net weight of the scrap.

Advanced Data Integration and Automation

Modern weighbridges are often connected to sophisticated software systems. This integration allows for the automatic generation of weight certificates, integration with ERP (Enterprise Resource Planning) systems, and real-time monitoring of site traffic.

- Unattended Operation: Drivers can use RFID tags or driver kiosks to weigh themselves without an on-site operator.

- License Plate Recognition (LPR): Cameras capture vehicle IDs automatically, linking them to specific weight records.

- Cloud Reporting: Management can access weight data from multiple weighbridges across different geographic locations from a single dashboard.

-

Add: Building 3, No. 355, Xiangshan East Road, Binhai Economic Development Zone, Cixi City, Ningbo, Zhejiang, China.

-

Tel: +86-18969402526

-

Phone: +86-0574-86817102

-

E-mail: [email protected]

English

English 中文简体

中文简体